The heart of

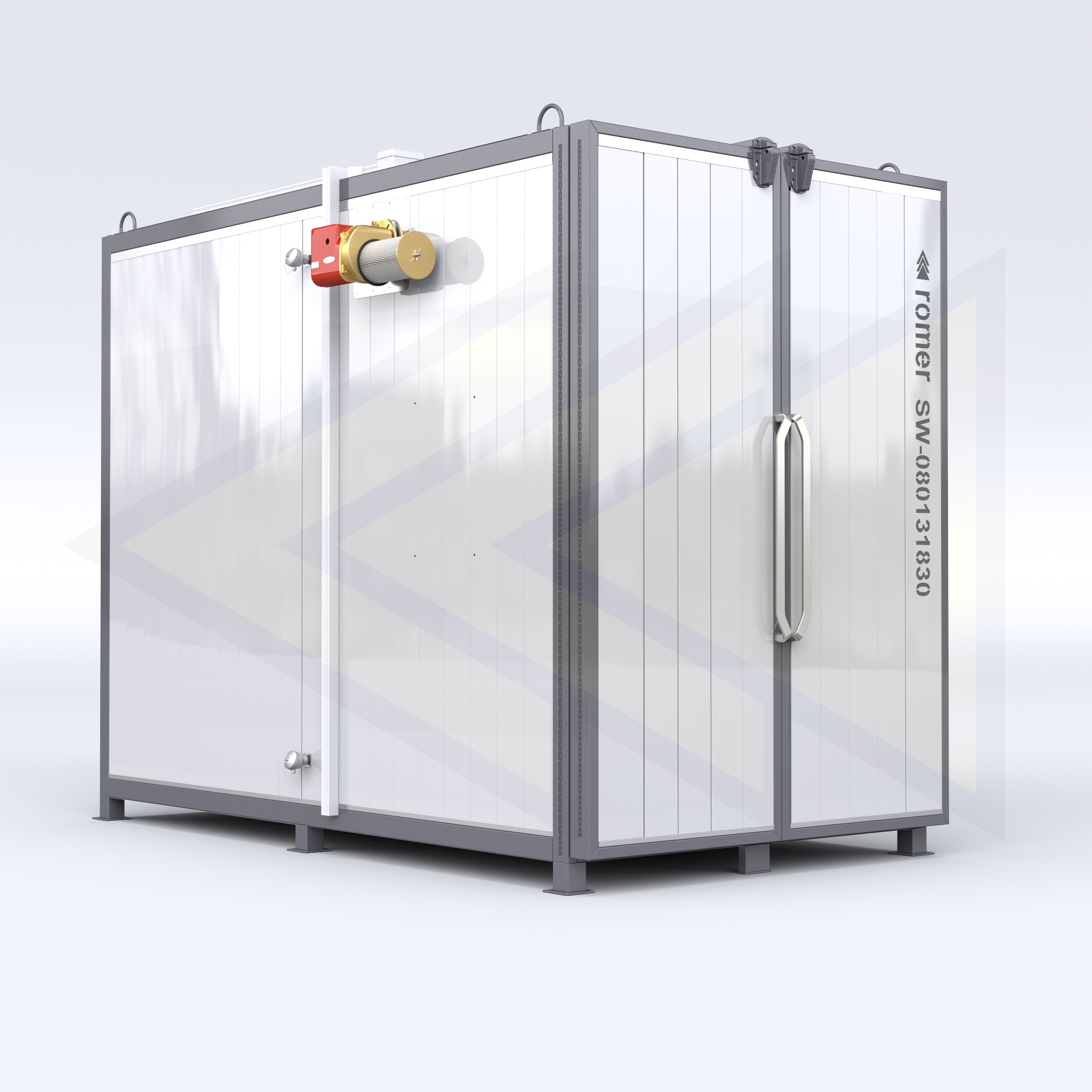

Chemical-free annealing oven

A manufacturer of enclosures for industrial electronics has implemented an oil oven made of 304 steel for annealing components at 600°C. Thanks to the neutral process conditions, expensive 316 steel was abandoned, reducing the investment cost by 35%, while maintaining full durability, safety and operational efficiency.

Romer case study

Chemical-free annealing oven

Assumptions:

-

Components are neutrally washed and dried before annealing - no risk of corrosion of 304 steel

-

Abandoning 316 steel as an unnecessarily expensive material in a neutral environment

-

Choosing a proven design without complex components prone to failure

Estimated effectiveness:

>95%, sealed chamber, canopy with active extraction, exhaust stack

~35% lower cost by using 304 steel instead of 316 steel

<30 minutes to reach 600°C

Estimated at over 10 years

Proposed solution:

At the plant, which manufactures housings and covers for industrial electronic apparatus, metal components after laser cutting and bending are cleaned in mild demineralised water-based solutions with a degreasing agent. The process does not involve the use of aggressive chemicals and the workpieces are dried in a convection tunnel before annealing.

The purpose of annealing is structural stabilisation and stress reduction in the material, which improves subsequent dimensional repeatability during assembly. The process takes place at 600°C and lasts between four and six hours. The workpieces are fully dry and chemically inert when loaded into the chamber.

The use of 304 steel in the oven construction proved to be optimal - both technically and economically. The temperature resistance of this steel is completely sufficient for operation in the intended range. As there is no contact with chlorine, acids or pickling residues - the more expensive 316 steel did not have to be used. This reduced the cost of the oven by approximately 35%, without affecting durability or operational safety.

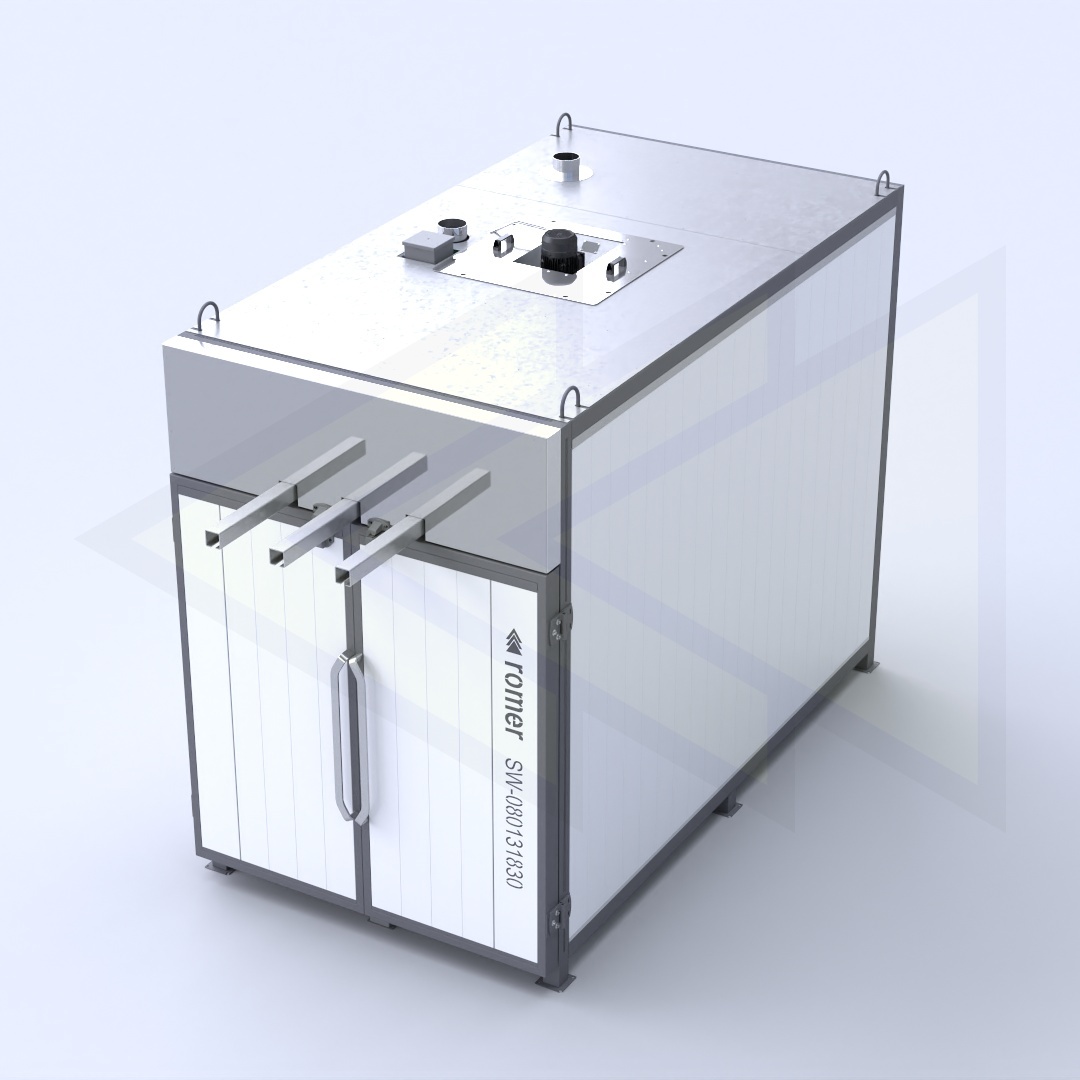

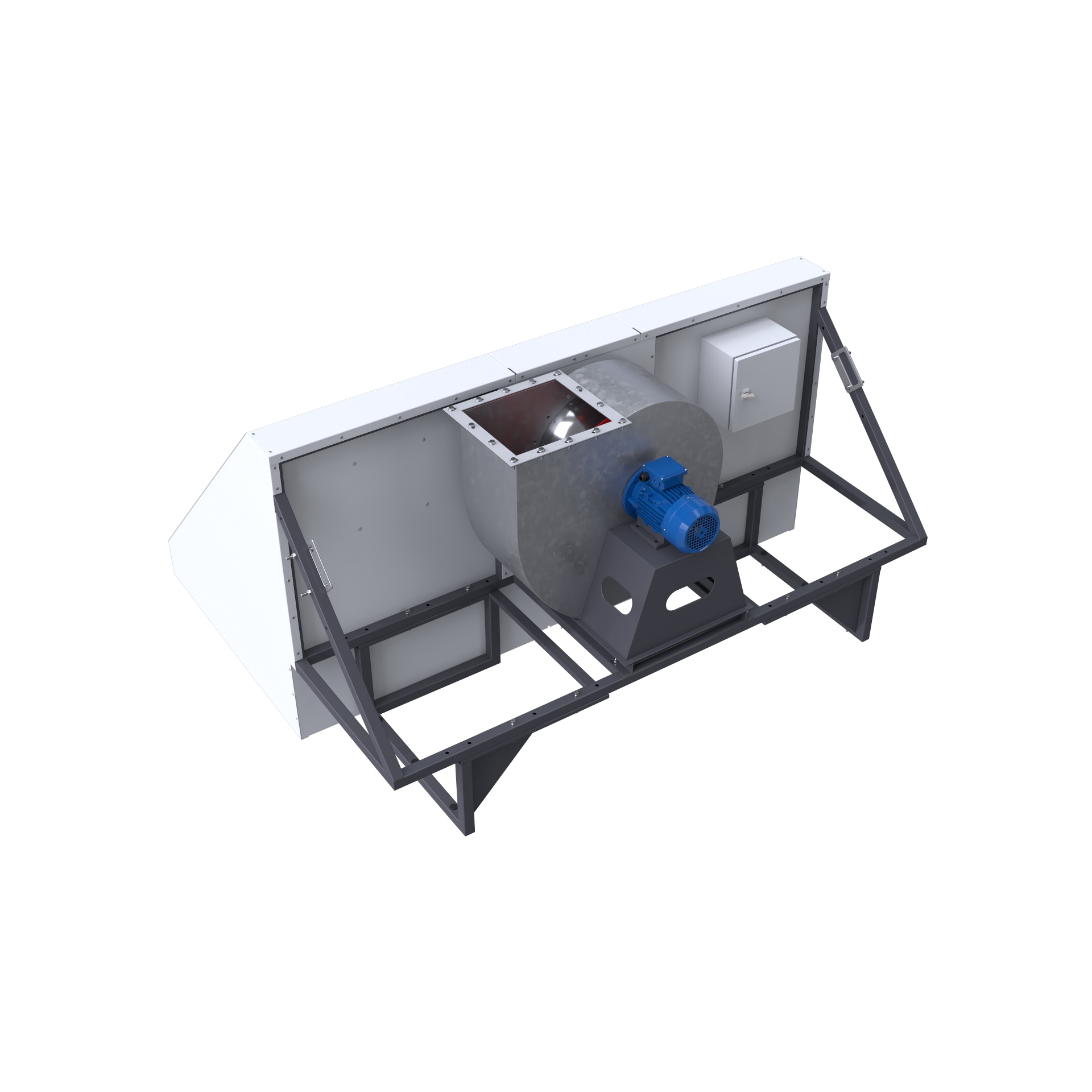

The oven chamber is lined with ceramic wool with a resistance of more than 1000°C, which provides very good thermal insulation. Heating is carried out by a thermal oil circulation system with a heat exchanger, which stabilises the temperature and minimises the risk of local overheating. In addition, there are electric locks for locking the chamber door during operation and a chimney for exhaust fumes outside the production hall. To improve working comfort, an active extraction hood is positioned above the door to capture any residual fumes before they are emitted into the hall.

Thanks to its clever design, the oven reaches operating temperature in less than 30 minutes, while ensuring even heating of the entire load. The simple design and the right choice of materials allow trouble-free operation with low maintenance costs for at least 10 years.

Check also:

Products used in this case study