Romer case study

Oven resistant to corrosive chemicals

Assumptions:

-

The company manufactures components for the medical industry with high purity requirements

-

The workpieces are chemically etched in solutions containing aggressive chlorine-based agents and organic acids

-

The details are wet and the chemistry is not completely neutralised before the heat process.

-

Warm-up times must be short and the working environment safe for operators.

-

The process requires an oven resistant to chemical fumes and safe for the operator

Estimated effectiveness:

>95% thanks to airtight chamber, active exhaust hood and hood over the oven door

Estimated at +10 years

Higher by ~30% compared to standard 304 steel, but the risk of premature corrosion is eliminated

Proposed solution:

At the company, which specialises in the manufacture of precision medical accessories, steel workpieces go into a chemical bath after machining, where they are etched and cleaned of micropollutants. This process is carried out using highly corrosive solutions that contain chlorine, nitric acid and additives to speed up the etching reaction.

In order to ensure the required surface properties and to reduce material stresses, the workpieces must be subjected to annealing in an oven almost immediately after removal from the bath - still wet, with chemical residues on the surface. This ruled out the use of classic industrial ovens, which would quickly corrode and pose a serious health risk to workers through fume emissions.

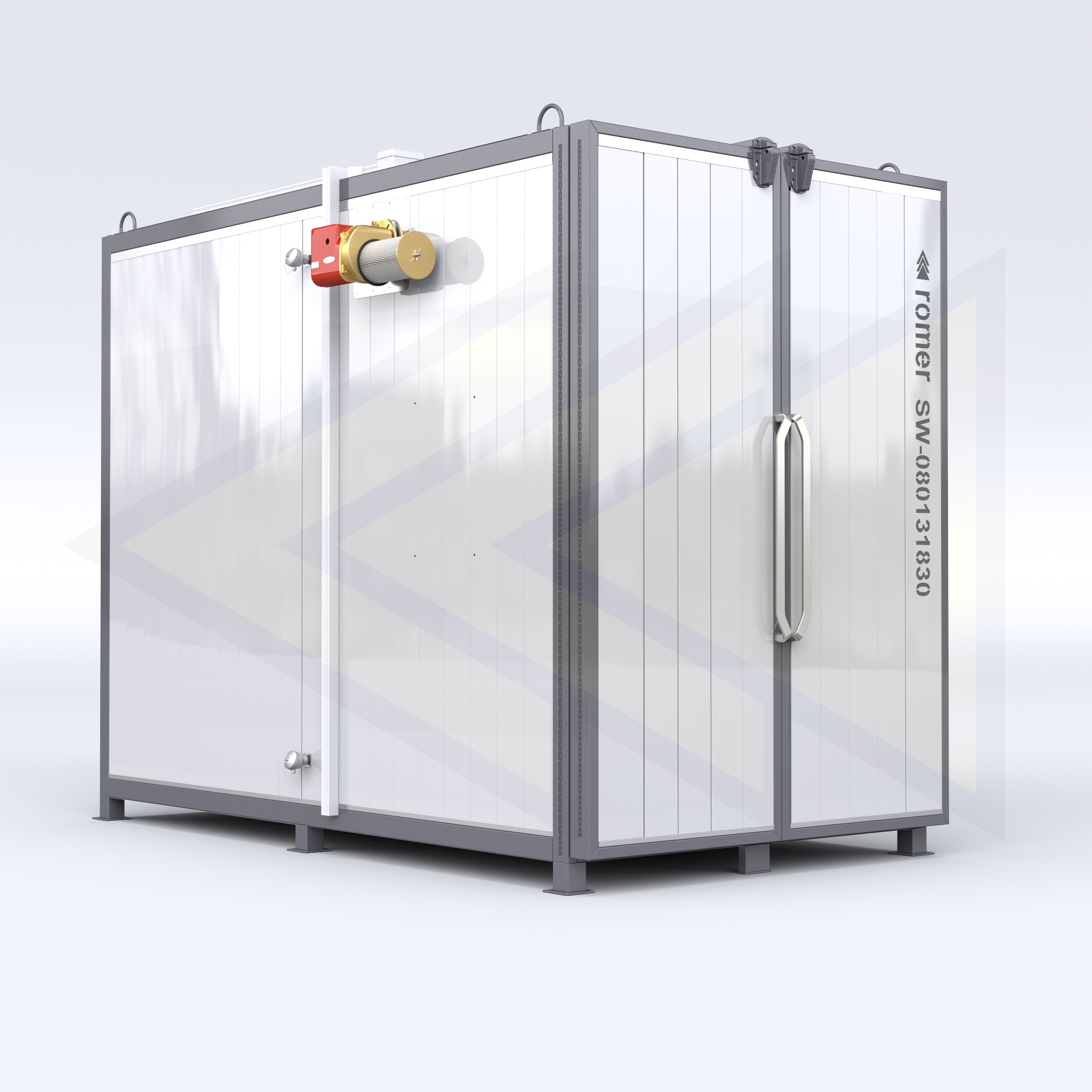

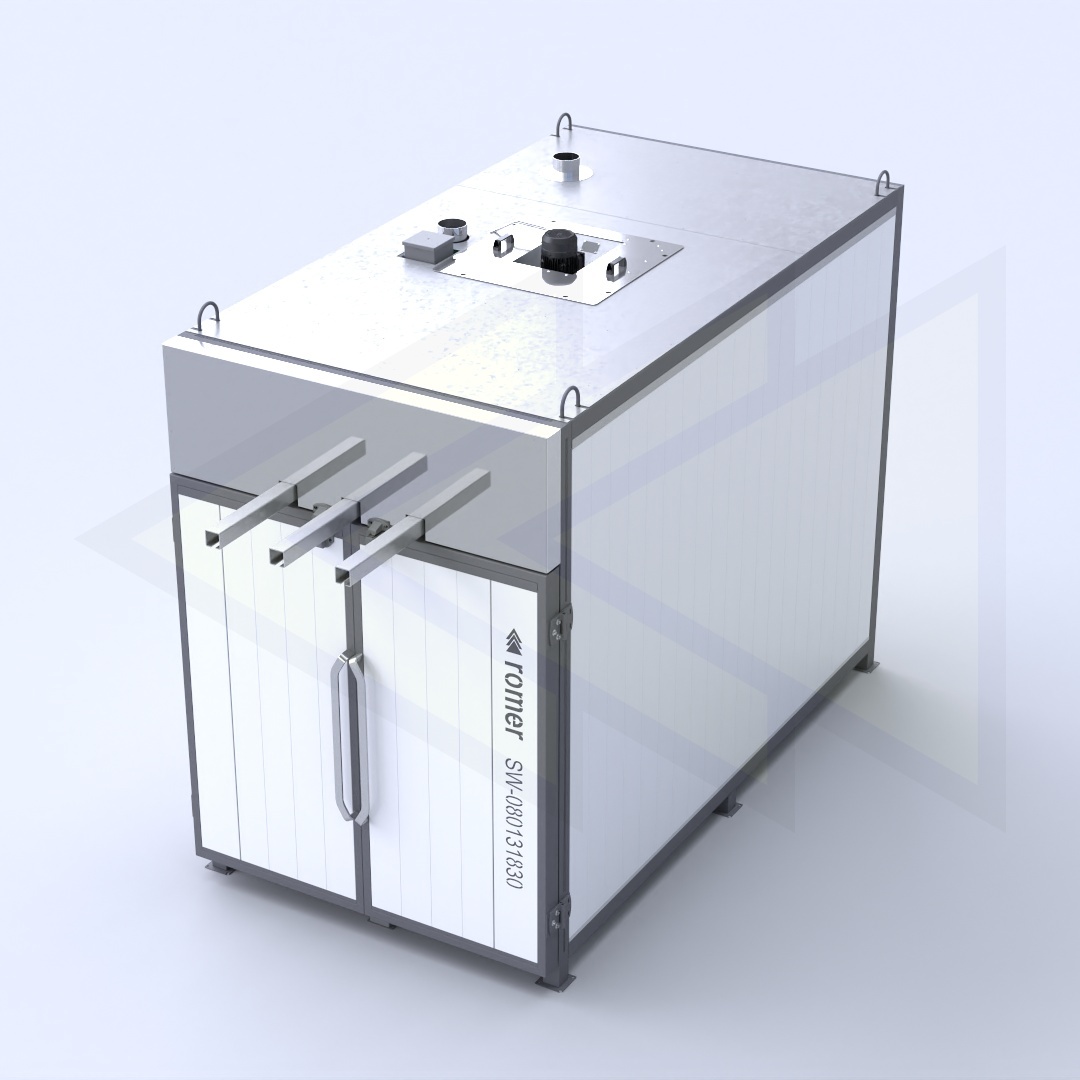

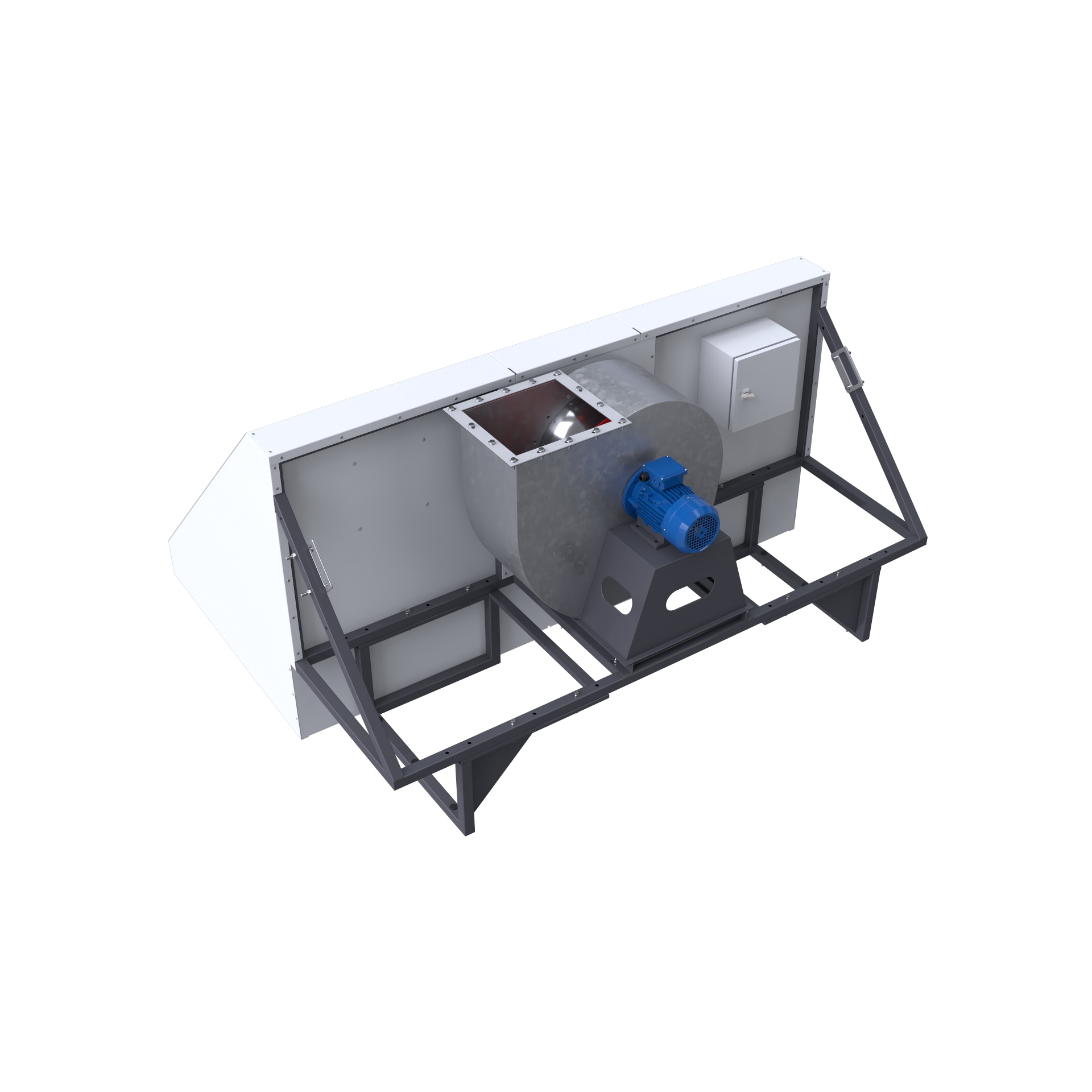

The solution turned out to be a oven made entirely of 316 stainless steel, which has exceptional resistance to chlorine and oxidising agents. The chamber was sealed and the pneumatic gasketed door effectively limits the emission of toxic gases during operation. In addition, a hood with exhaust system is installed above the oven, which discharges aggressive vapours directly into the ventilation system. An integrated fan with power control ensures that the temperature is quickly reached and evenly maintained throughout the chamber volume.

The entire chamber operates in a temperature range of up to 300°C, which allows not only effective annealing, but also the neutralisation of chemical residues from the surface of workpieces. The chamber insulation is made of glass wool, which, thanks to its thermal properties (resistance up to approx. 400-500°C), is an economically sound choice - cheaper and sufficient compared to the more expensive ceramic wool used in high-temperature ovens.

Thanks to the materials and safety features used, the oven can operate continuously under harsh conditions without the risk of premature degradation or danger to operators.

Check also:

Products used in this case study