The heart of

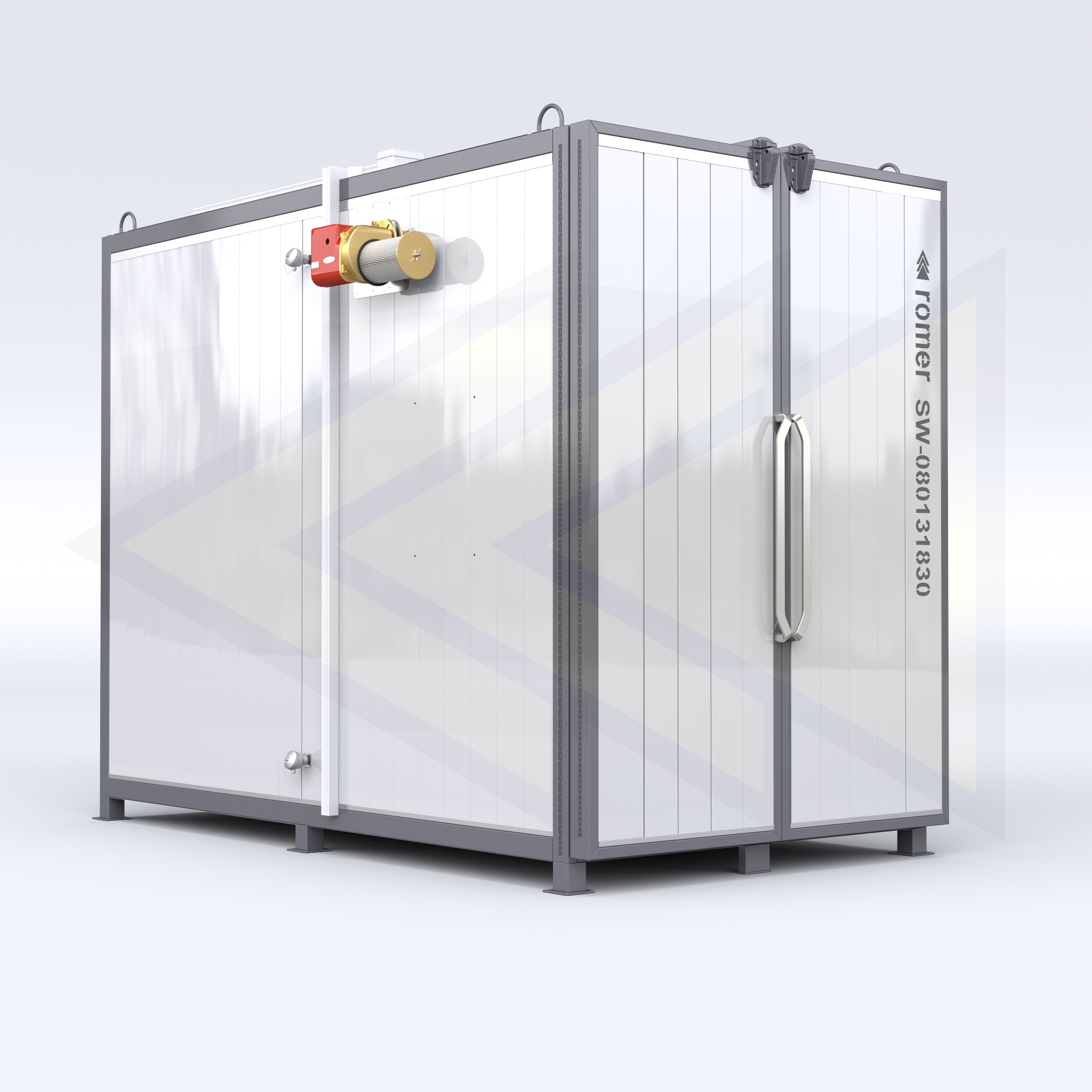

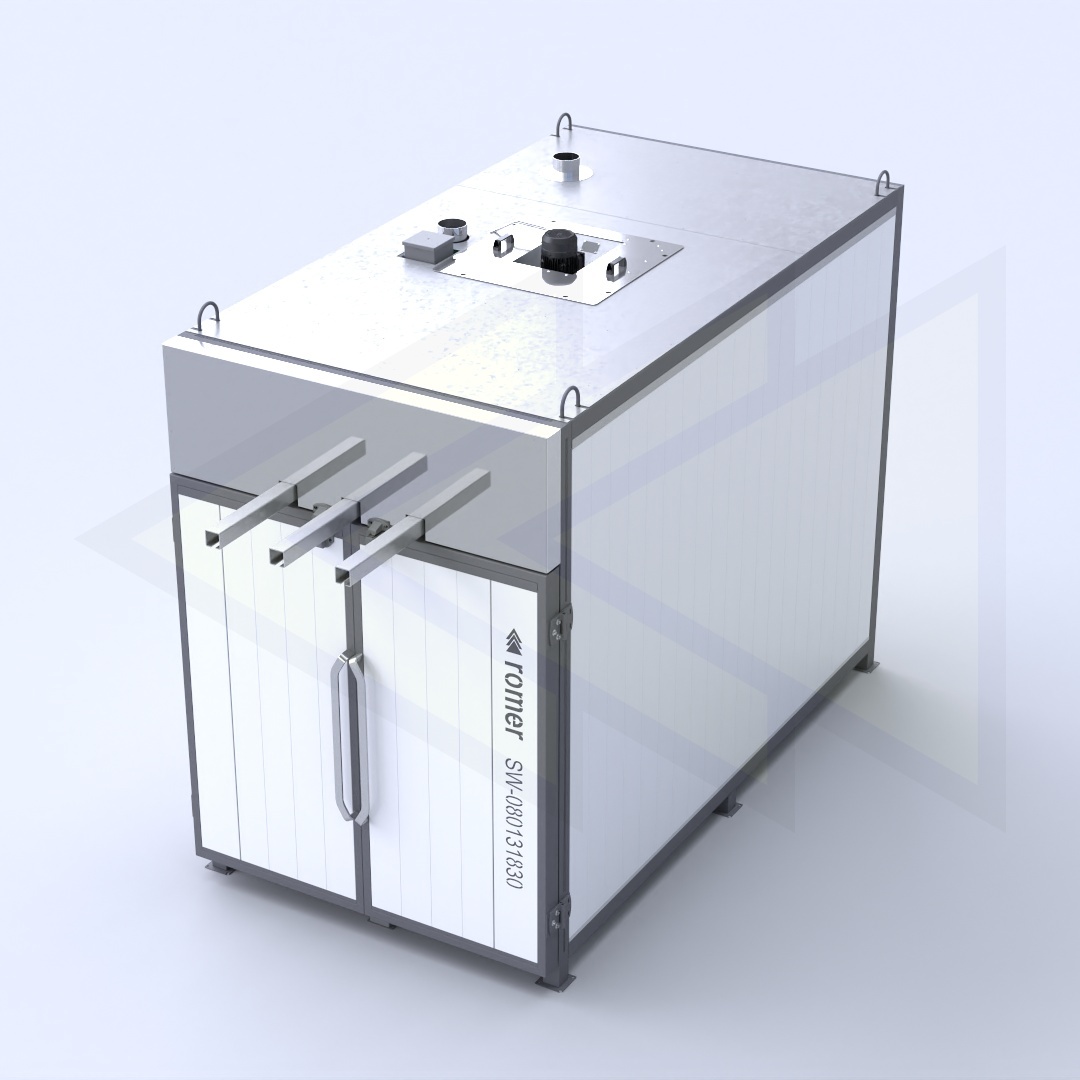

Mobile oven without floor

A manufacturer of heavy workpieces has implemented a mobile floorless oven that surrounds the component on site. The process takes place without the need for transport, with full temperature control and savings in time, material and space.

Romer case study

Mobile oven without floor

Assumptions:

-

The details could not be moved due to the weight, dimensions and method of assembly.

-

The process did not exceed 400°C, so glass wool insulation was sufficient.

-

High repeatability and precise temperature control were required - MTS and VFD systems had to be used.

Estimated effectiveness:

Reduction of >70% due to elimination of detail manipulation

<±3°C thanks to MTS

Dynamic, optimised by VFD

Reduced to a minimum - the oven does not require a permanent, dedicated station

Proposed solution:

A technological challenge arose at a company producing large-scale components for the energy and transport industry: components weighing several tonnes, fixed in a technological framework, could not be transported to a classic oven without risk of damage, costly downtime and logistical complications.

Instead of moving the workpiece, the company decided to implement a mobile oven without a floor, which moves into the workpiece and covers it from above and on all sides. The design, based on five insulated walls with sealed doors, creates an enclosed heating chamber without the need to dismantle the stand.

The oven uses glass wool, matched to temperature requirements below 400°C, providing effective thermal insulation at a lower material cost. Processes carried out in the chamber include annealing, drying, polymerisation and stabilisation.

For full control of thermal conditions, an MTS system with multi-point temperature measurement and a VFD system were used, which controls the fan depending on the process stage. This configuration optimised both the heating quality and energy efficiency of the entire system.

Check also:

Products used in this case study