The heart of

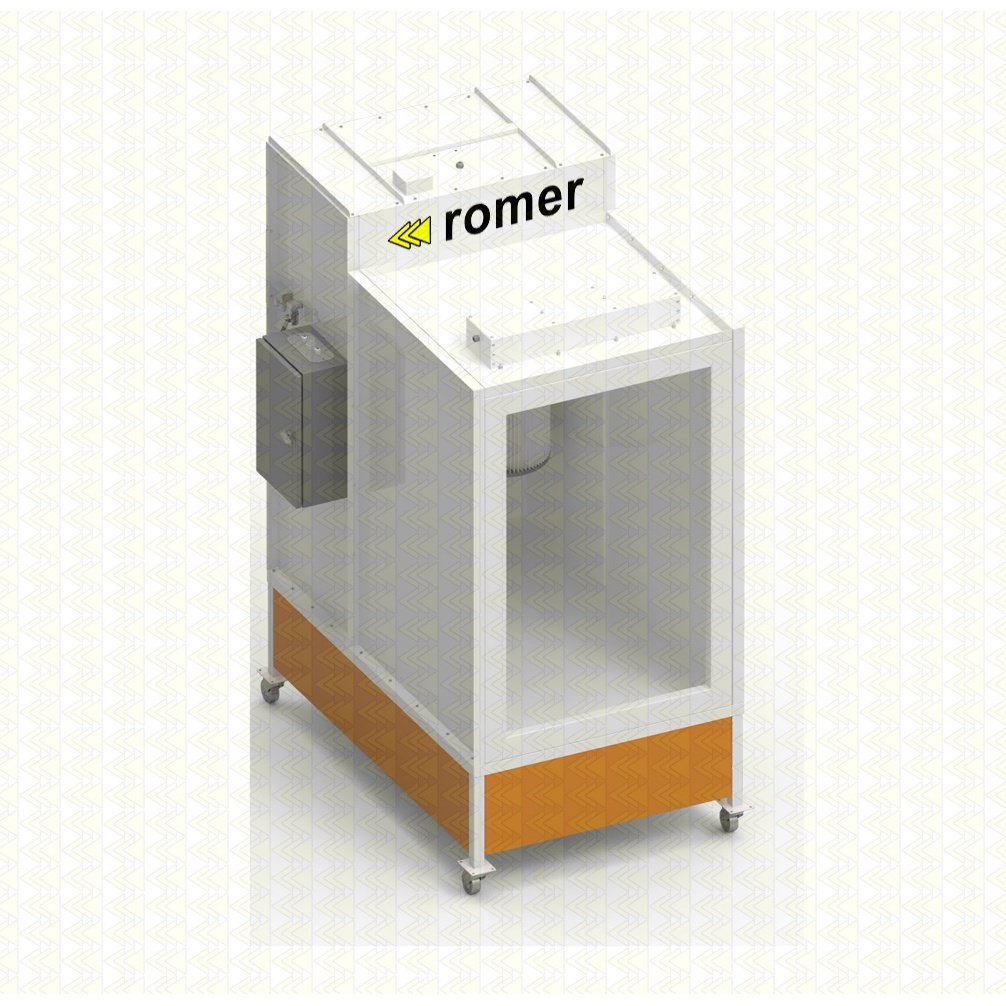

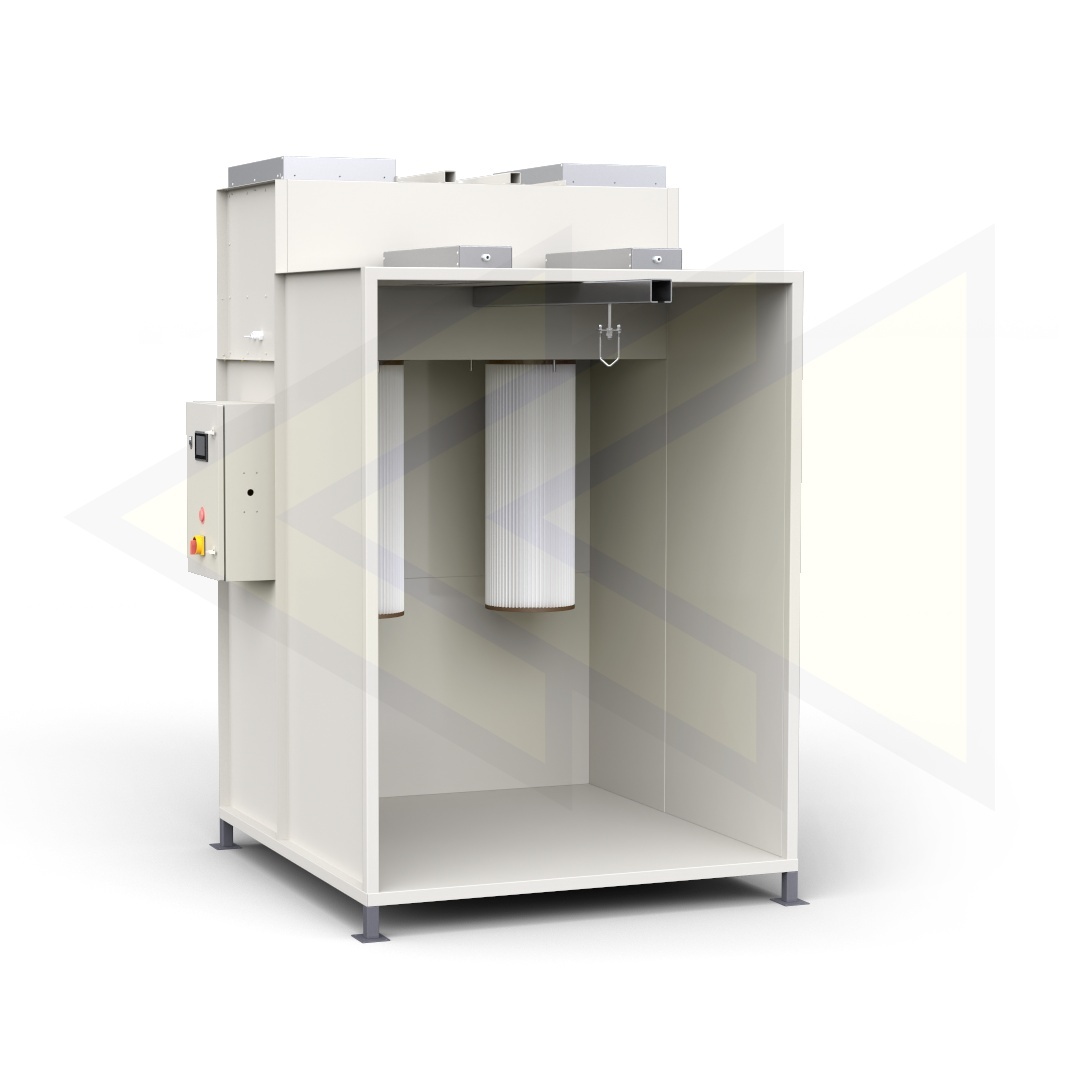

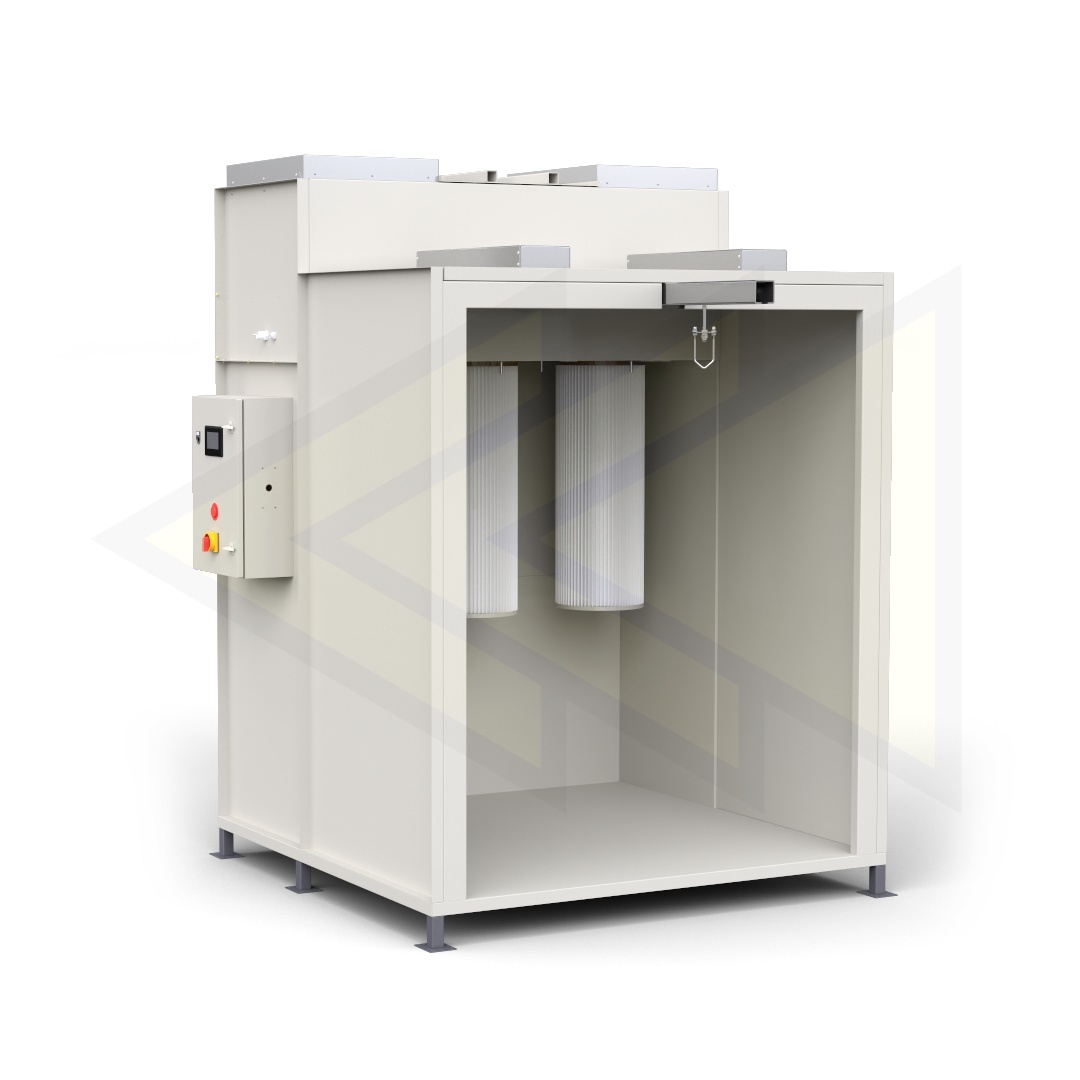

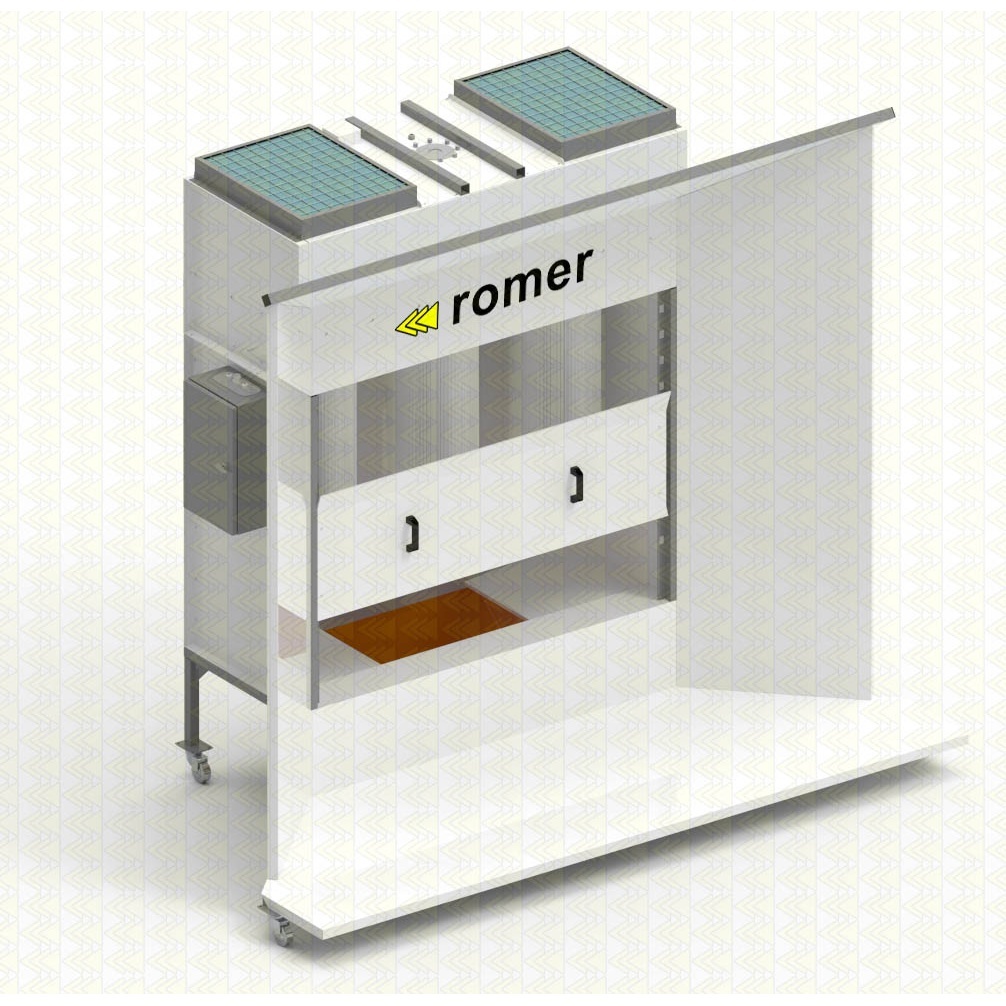

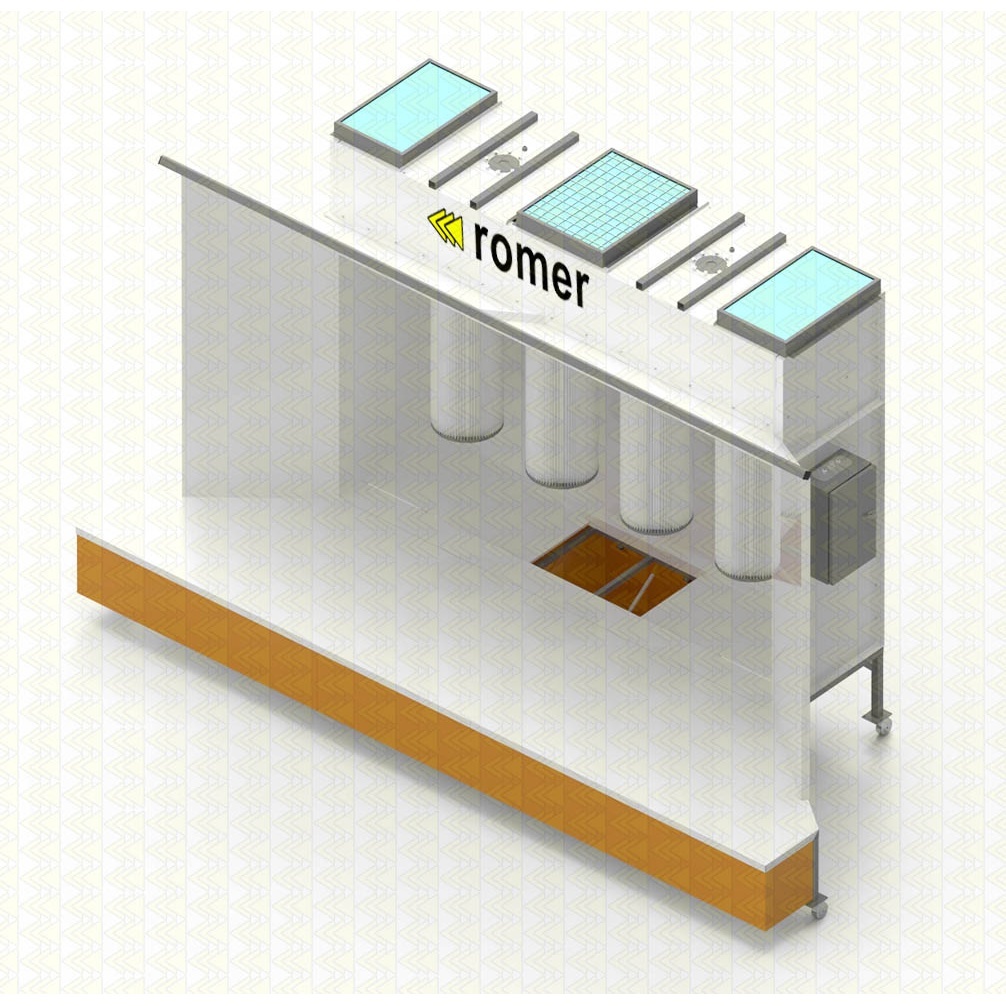

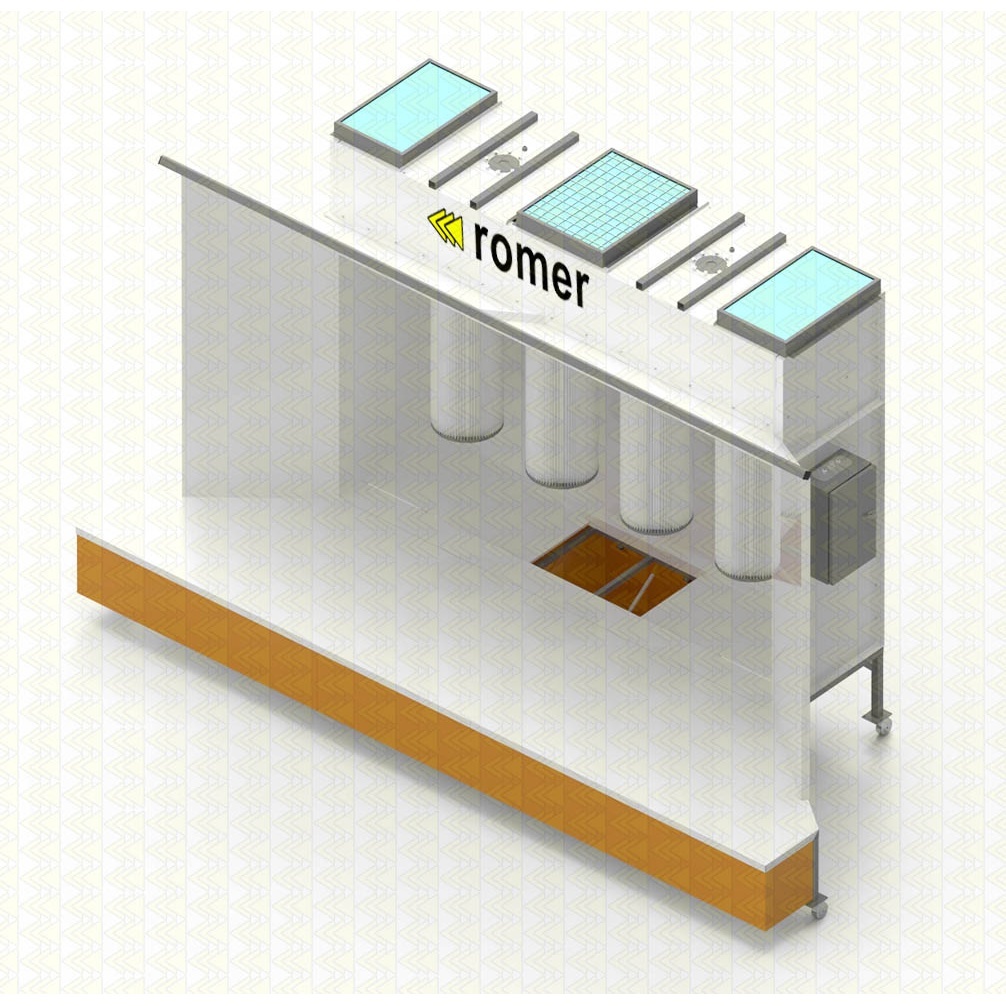

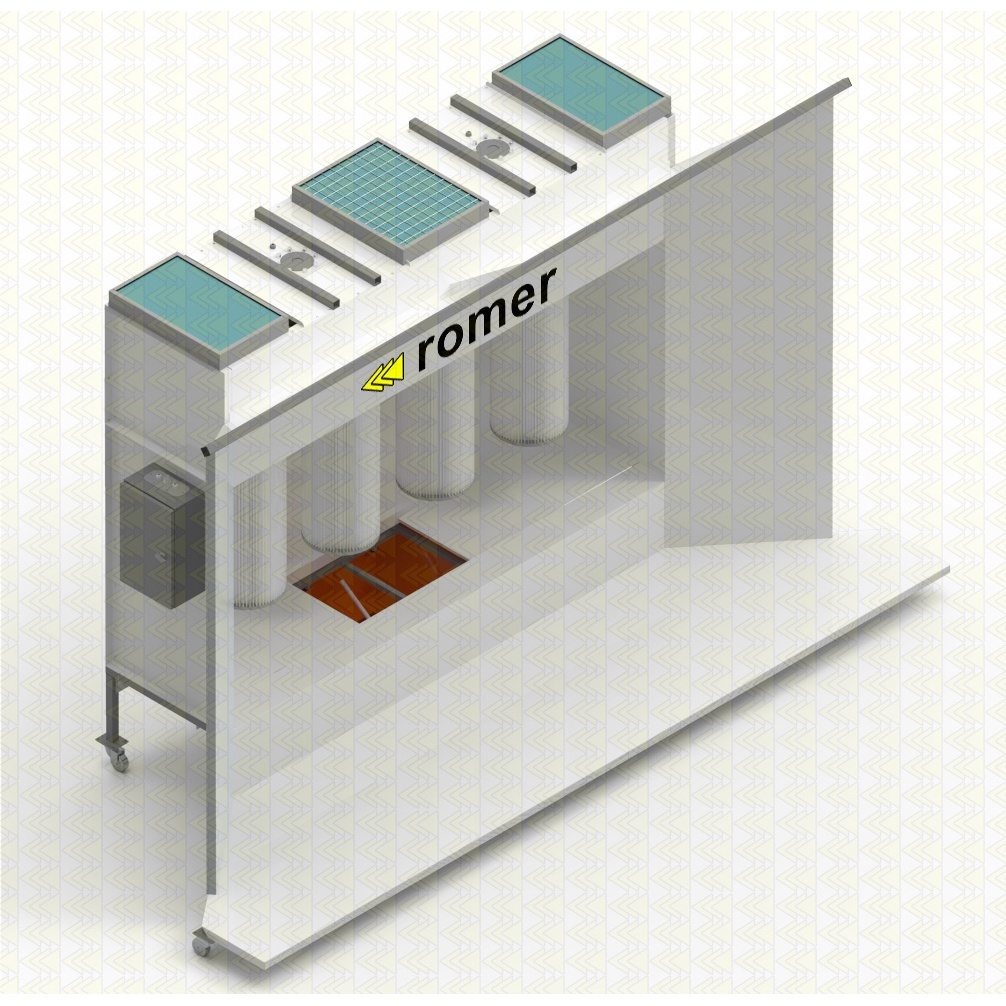

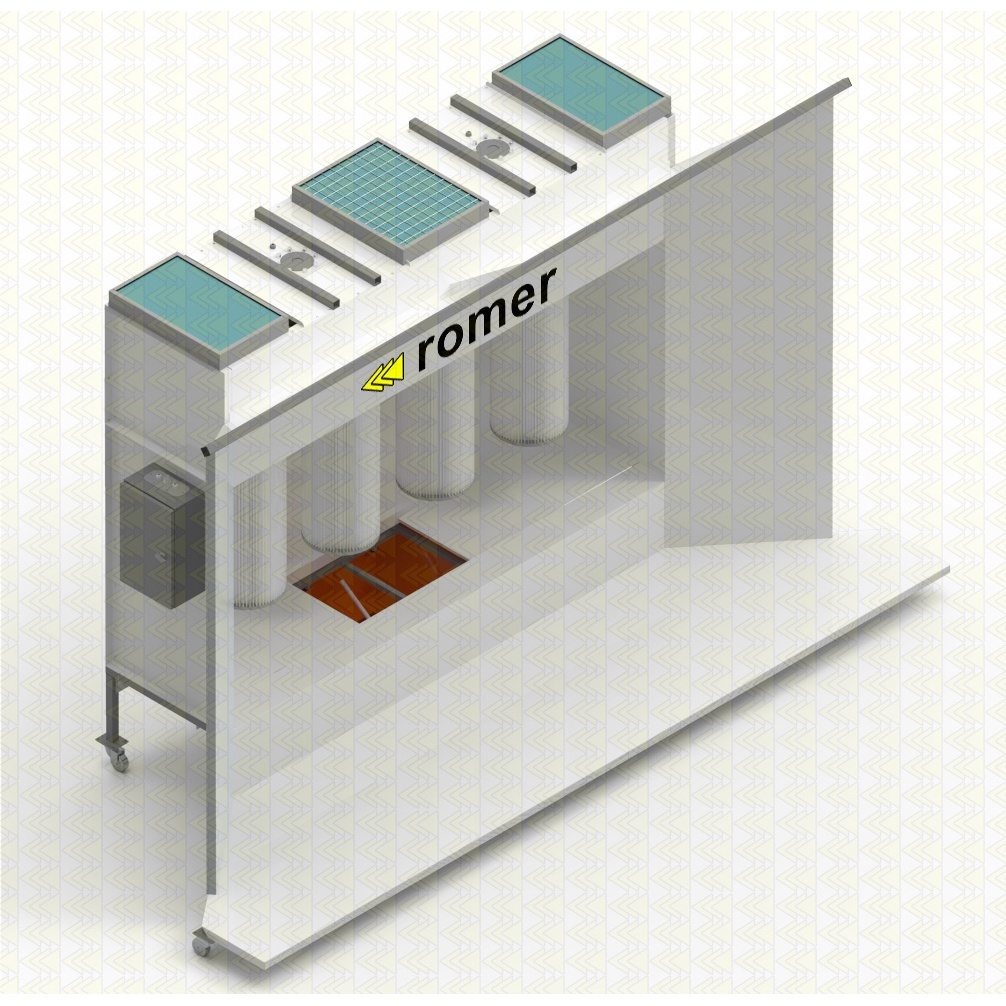

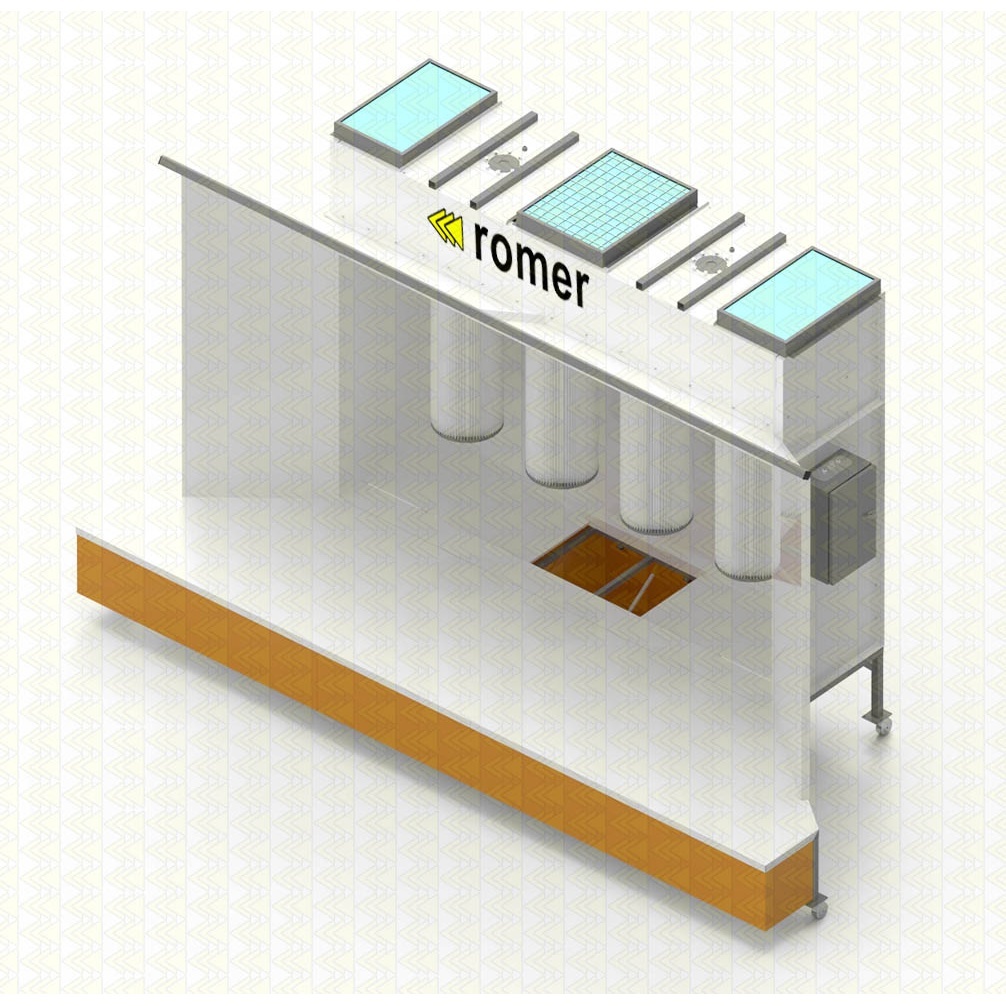

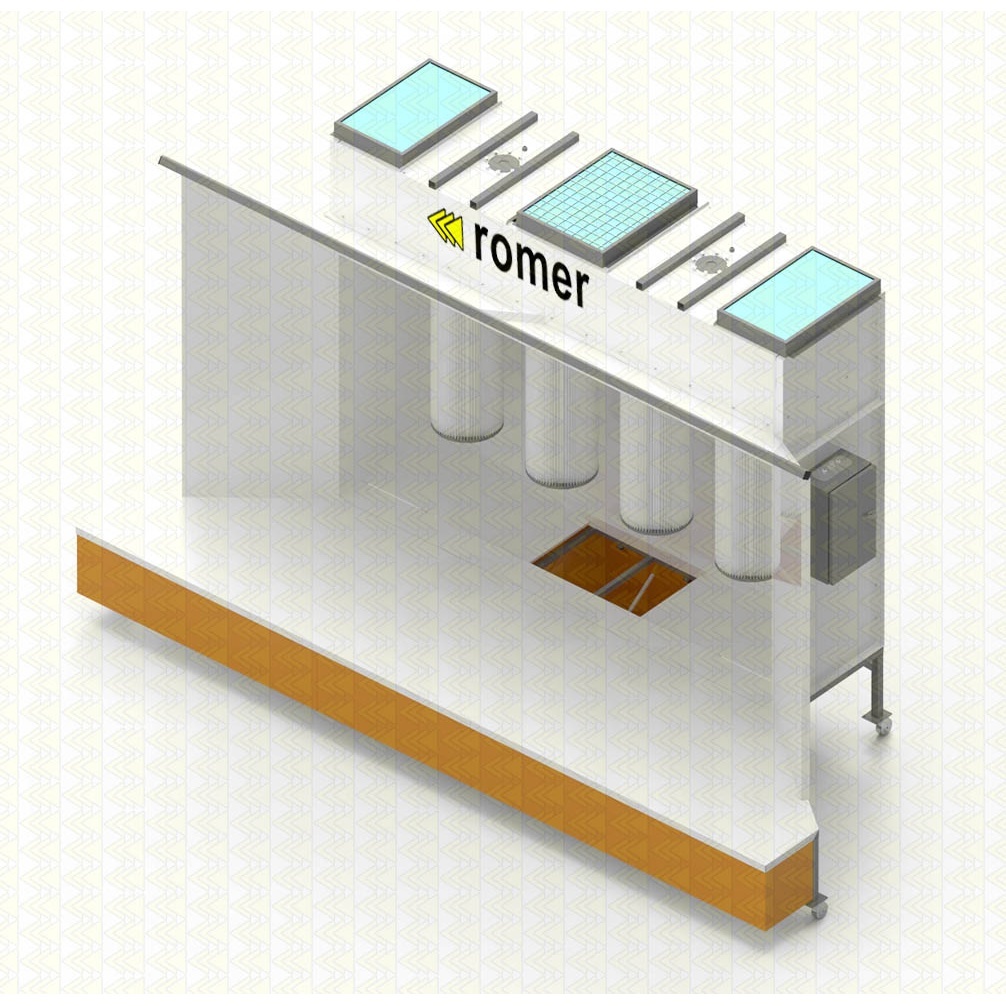

Powder booth with antistatic construction

The company, which manufactures metal electronic parts, implemented an anti-static powder booth with a plastic structure to eliminate the problem of surface electrification, significantly improving the painting process and creating conditions suitable for working in an environment where static electricity was a serious problem.

Romer case study

Powder booth with antistatic construction

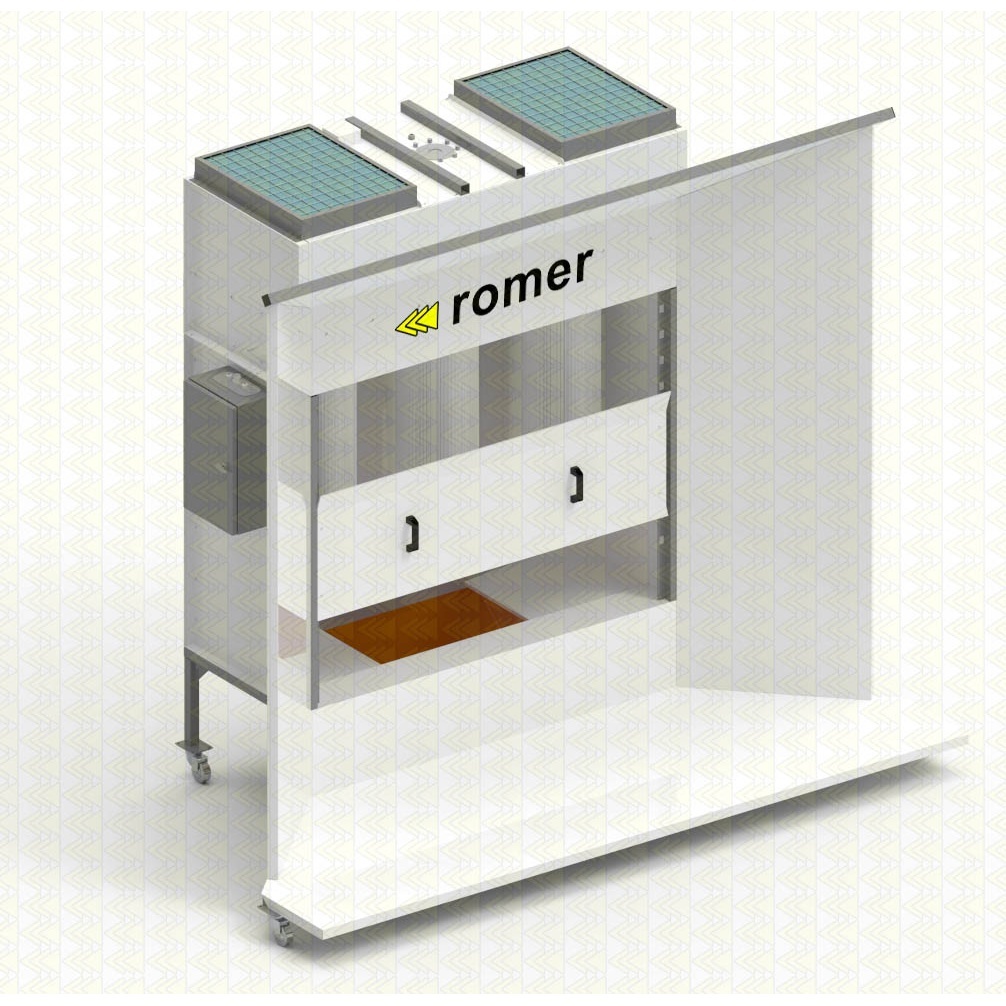

Assumptions:

-

The client required a completely non-metallic, anti-static design

-

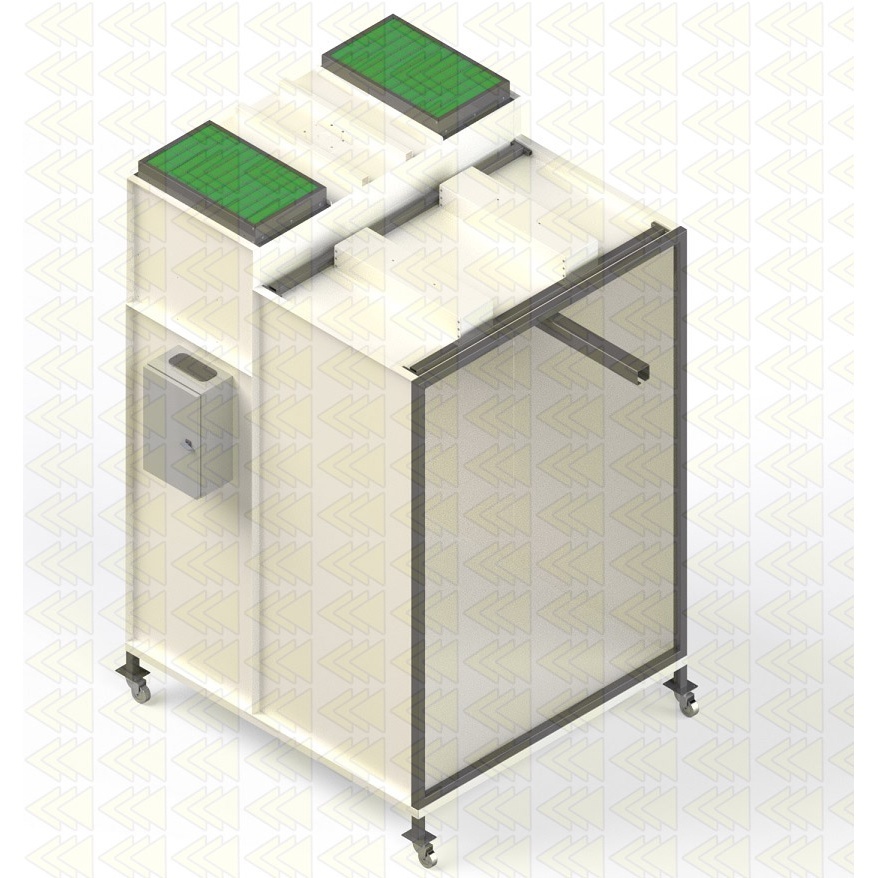

The cabin had to comply with stringent ATEX standards - the need for hazard detection and automatic power shutdown

-

The process requires fast and efficient regeneration of powder filters and minimisation of powder loss.

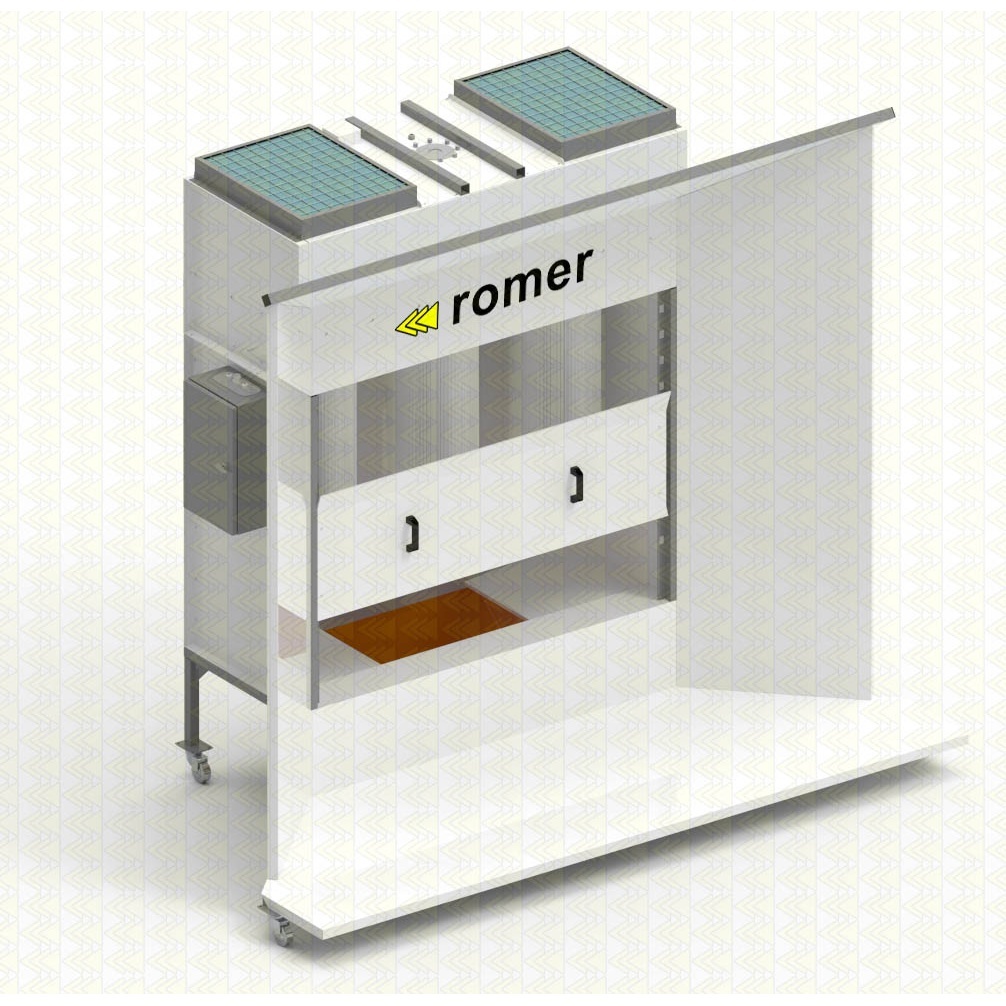

Estimated effectiveness:

100% elimination of metal components has reduced surface electrification to a minimum

>80% shorter filter cleaning time thanks to ROMER JET system

+300% polyester filter life compared to cellulose filters

More than 90% of unused material goes back into circulation

<2 seconds - this is how long it takes the camera to detect and initiate a power cut

Proposed solution:

At a company involved in the precision painting of electronic components, one of the key problems was the instability of the powder coating application process caused by electrification of the steel booth components. Excessive electrostatic charges caused uneven powder deposition, increased dusting and the risk of uncontrolled spark jumps.

In response to these challenges, a spray booth made entirely of plastic with antistatic properties was implemented, almost completely eliminating the problem of charge build-up on the working walls. This has significantly improved the quality of coatings and operator safety.

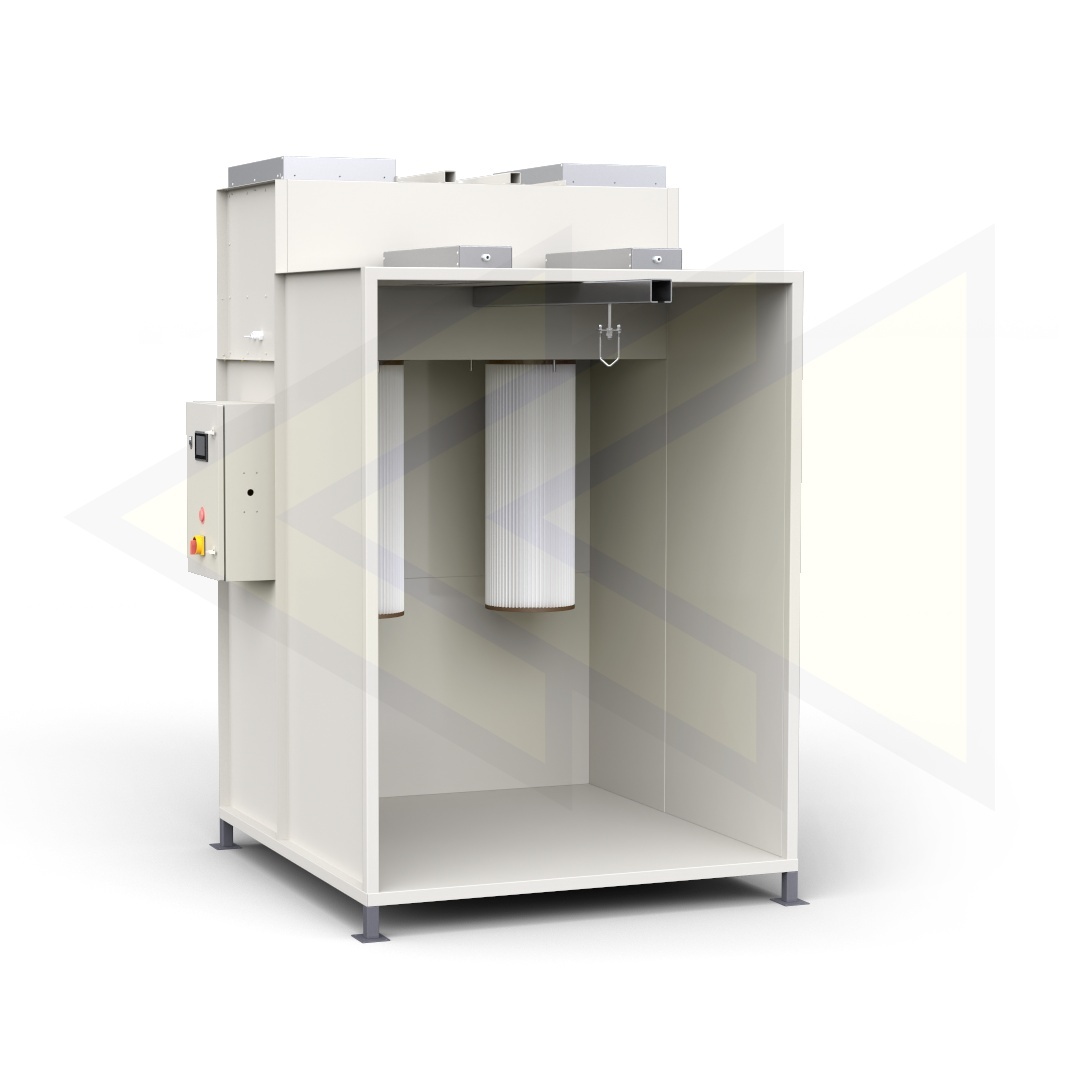

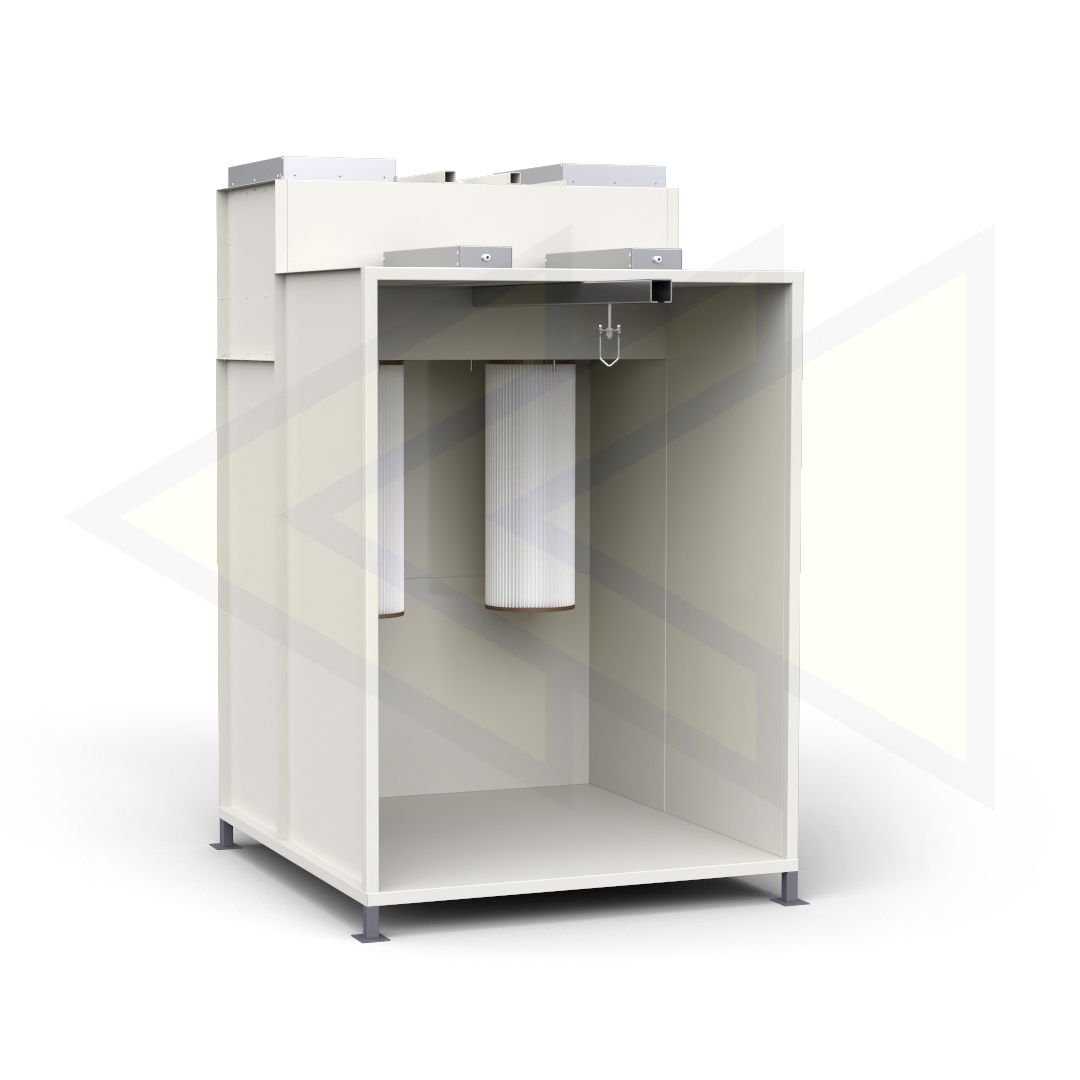

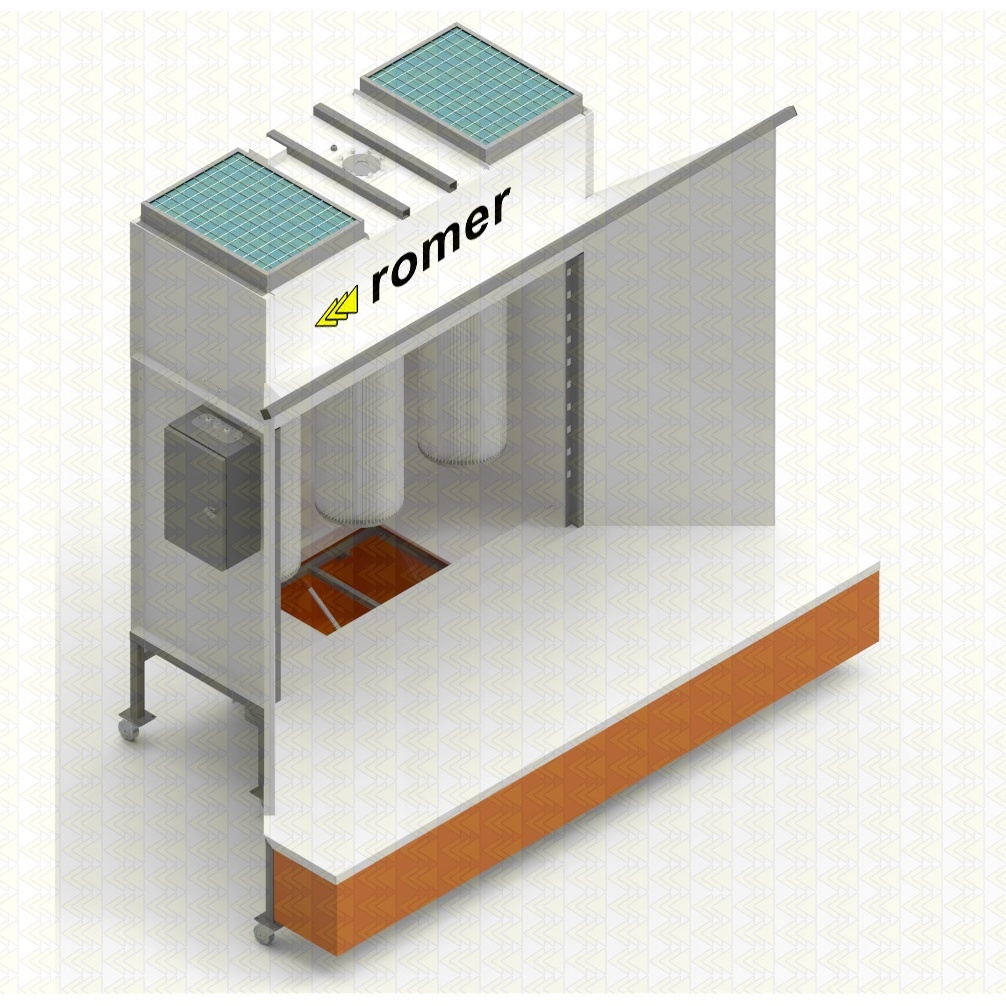

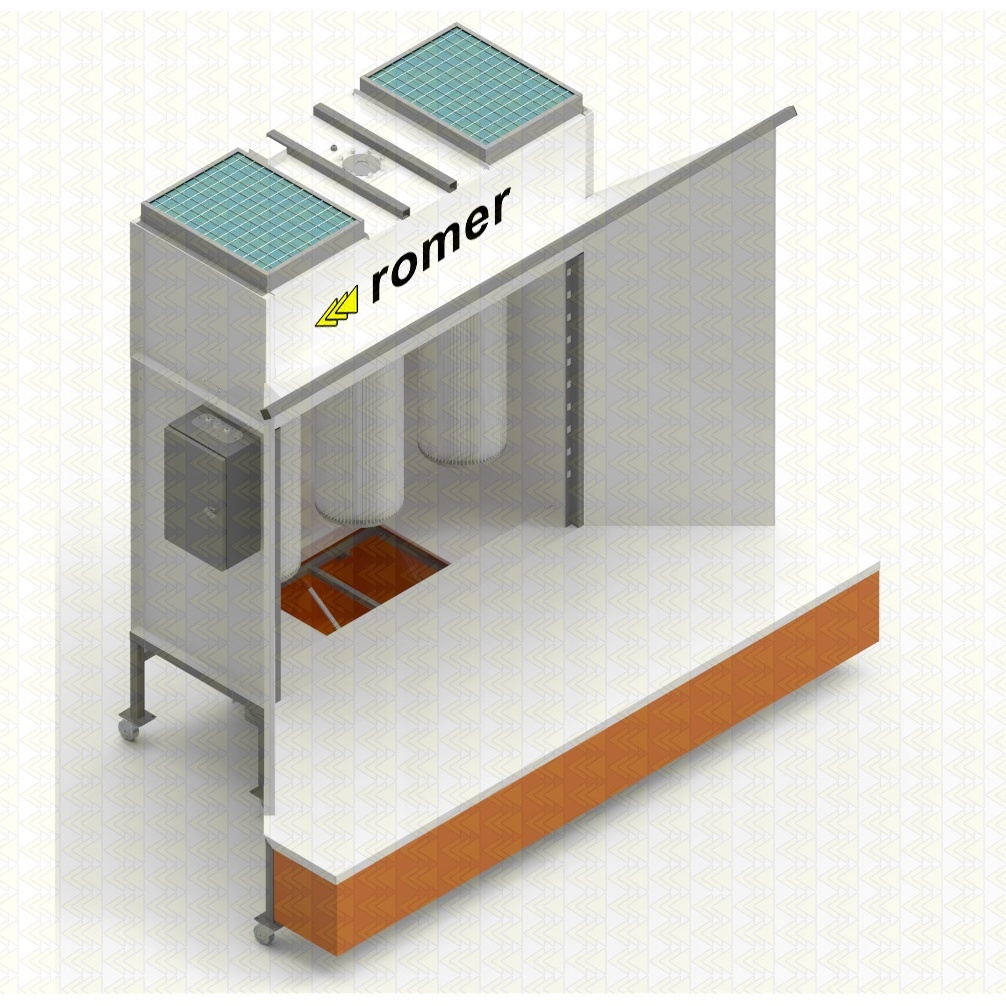

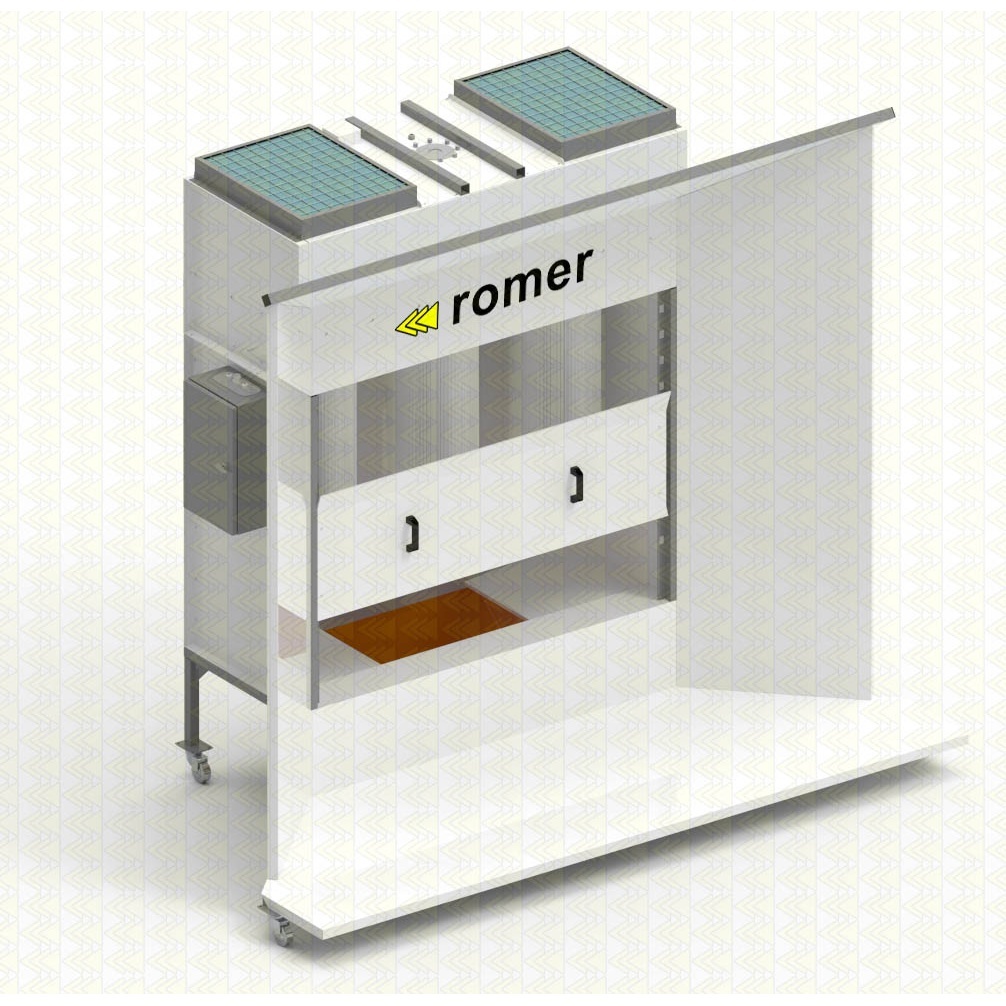

The cabin is equipped with the ROMER JET system, a patented filter cleaning solution which effectively removes embedded powder from the entire filter surface using a powerful pulse of compressed air. Unlike conventional systems, ROMER JET does not require process stops or multi-stage purging - the cleaning pulse lasts for fractions of a second, reducing downtime and increasing machine availability.

The polyester filters used provide higher resistance to moisture, a longer service life and greater separation efficiency than cellulose filters, which wear out quickly and are prone to moisture.

To increase the level of safety, a fire camera has been installed in the cabin, which automatically cuts power to the entire system in the event of fire detection or a rapid rise in temperature, protecting the installation and workers.

The system has also been supplemented with a powder recovery tank, which allows unconsumed paint to be efficiently collected and reused. This translates directly into lower material costs and less waste.

Designed in this way, the booth allows for a stable, reproducible and clean application process, reduces the risk of malfunctions and meets stringent standards for explosion protection and electrostatic charge control.

Check also:

Products used in this case study