The heart of

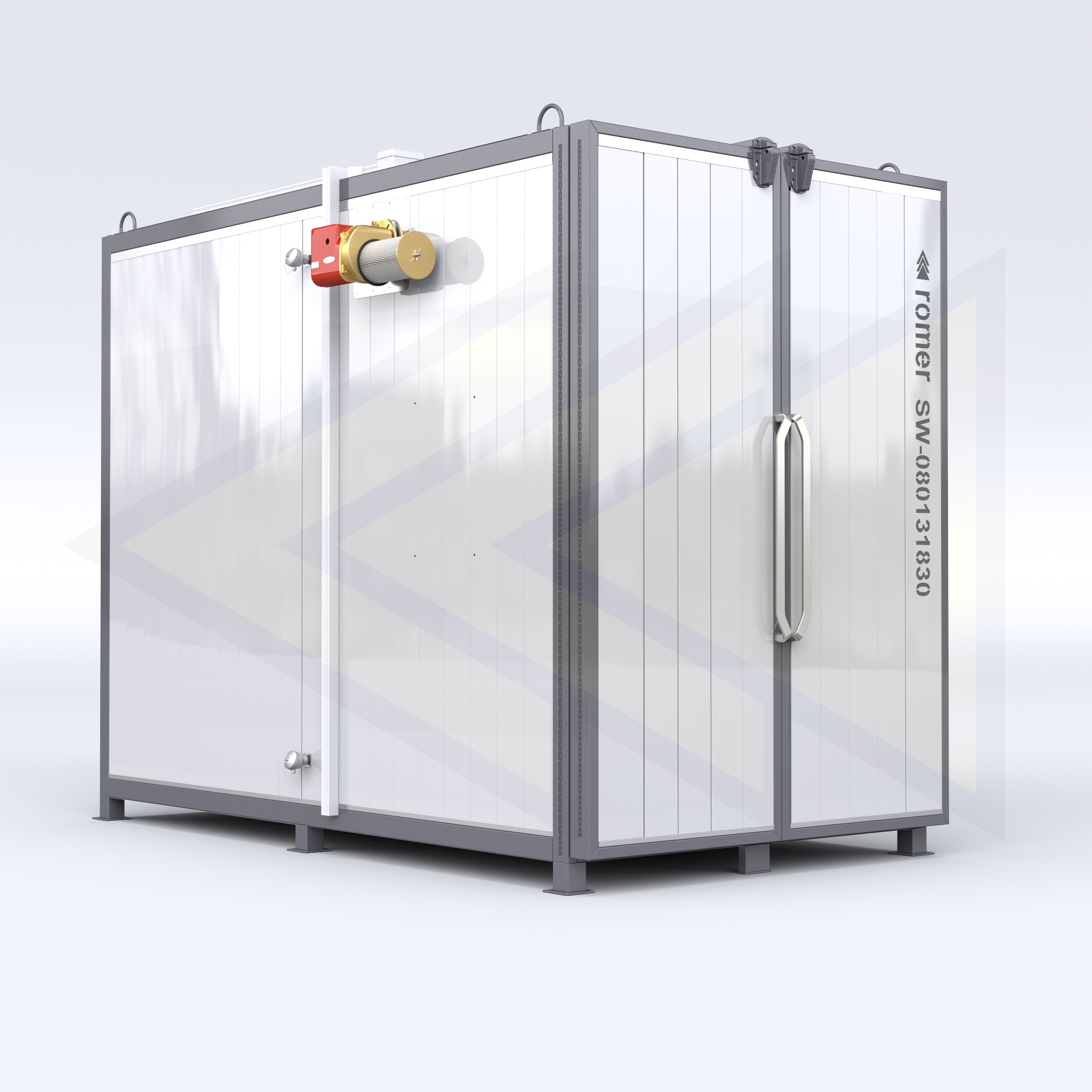

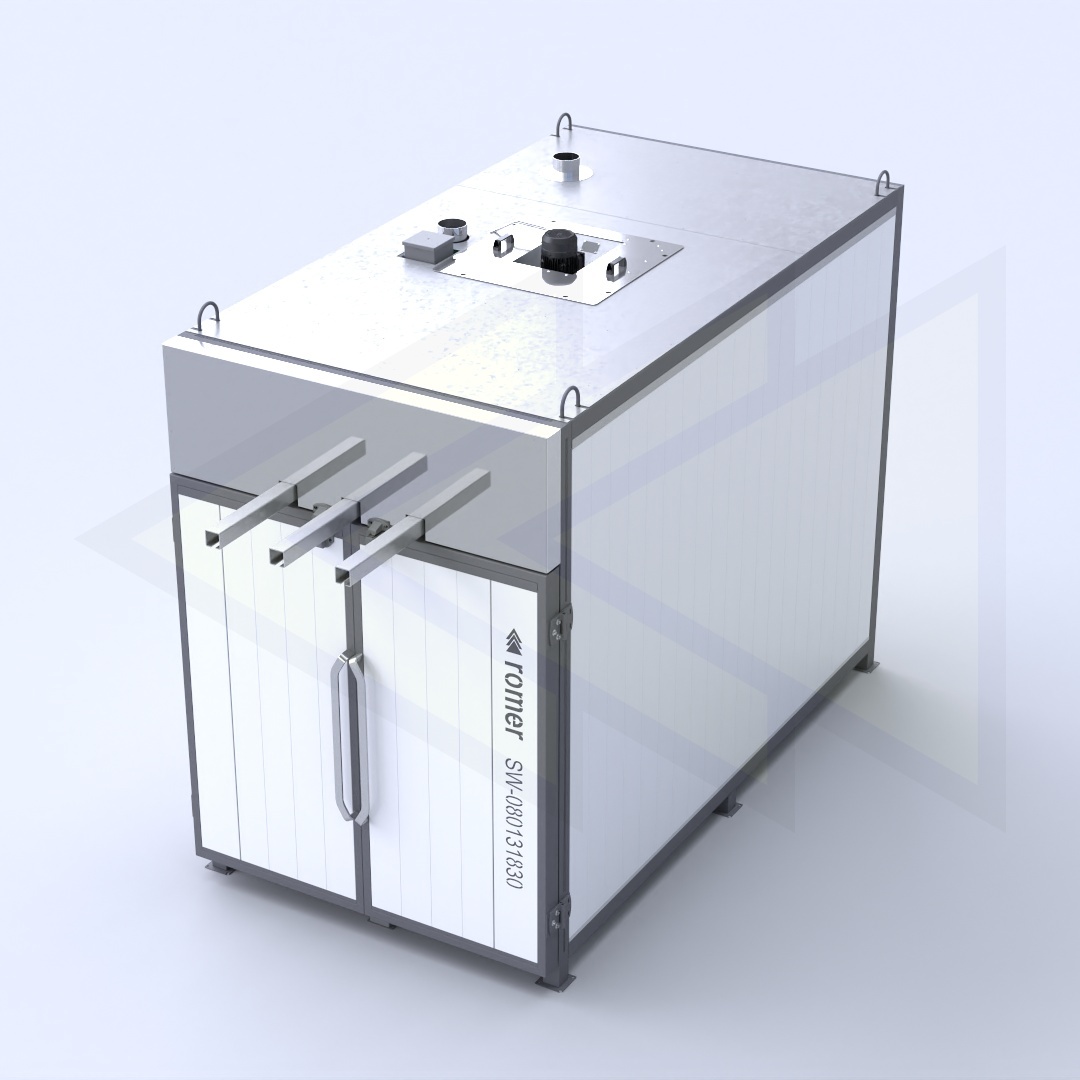

Semi-automatic oven with conveyor belt

A manufacturer of steel assembly components has implemented a semi-automatic oven with a conveyor belt, where the workpieces are automatically annealed and moved through the chamber before falling into a container. The solution has significantly increased process efficiency with minimal operator input, leaving the way open for further automation.

Romer case study

Semi-automatic oven with conveyor belt

Assumptions:

-

Automating the powder annealing process in the production line.

-

Performance had to significantly outperform the batch oven without sacrificing the quality of the coatings.

-

Possibility of later expansion with full automation.

Estimated effectiveness:

Increase to 3-4× that of the batch oven

Automated loading, manual workpiece removal - limited operation to one operator

No downtime - the oven runs continuously

Prepared acceptance points for future automation application

Proposed solution:

At a plant producing steel abutments and assembly components for the electrical engineering industry, there was a need to increase the efficiency of the powder coating curing process. The existing batch oven was limiting the work rate and causing a bottleneck in the thermal curing stage of the coating.

The company implemented a semi-automatic tunnel oven with a conveyor belt, in which the parts are automatically moved through the heating, baking and final cooling zones and then drop into a collection container. Thanks to this design, it is possible to quickly reduce the temperature of the workpieces after the process without the risk of coating deformation.

The process runs continuously without downtime - the oven functions as long as the line is running. The workpieces do not have to be hung or manually loaded, which completely eliminates the time-consuming handling stage and significantly simplifies work organisation. The entire system is operated by one operator, with a maximum of two at full load.

Thanks to the conveyor belt, continuous operation and final cooling, the company has achieved high productivity, repeatability and process stability, while maintaining ease of use and low costs.

Technologies used

Check also:

Products used in this case study