The heart of

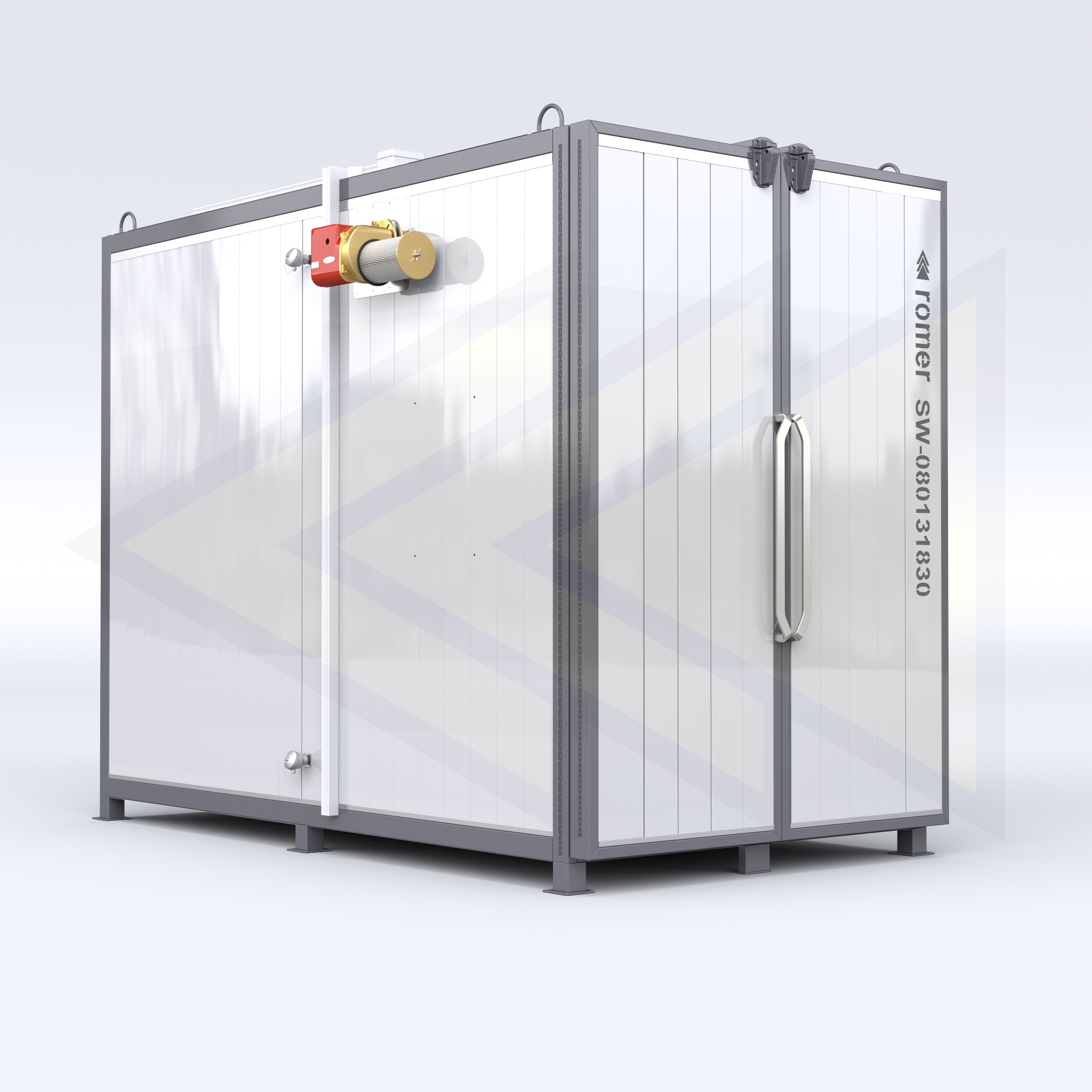

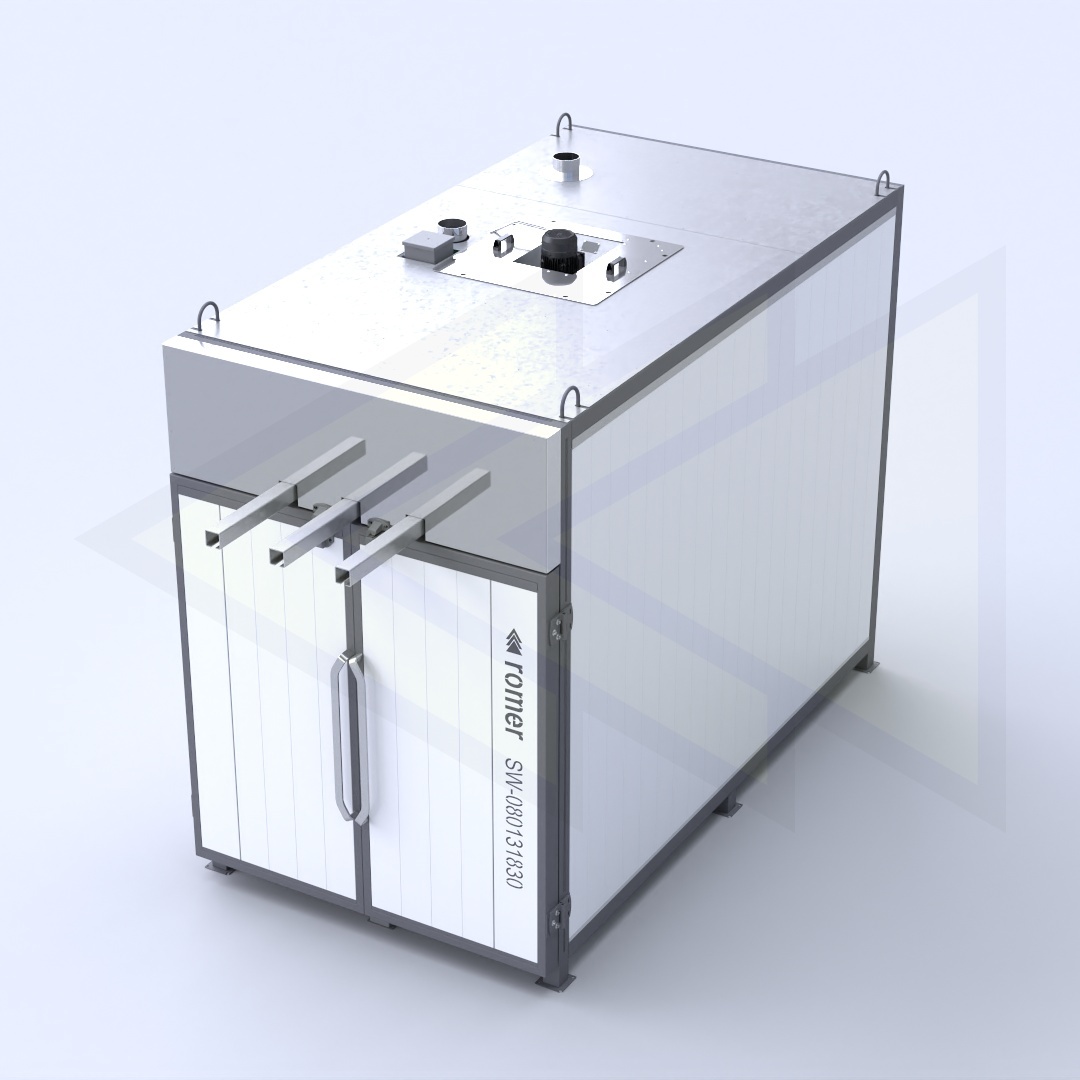

Steel cabin designed for years of service

The metal construction manufacturer relied on the carbon steel paint booth as a durable and hard-wearing solution for intensive multi-shift work - ensuring stable application conditions without the need for costly and delicate specialised materials.

Romer case study

Steel cabin designed for years of service

Assumptions:

-

Production conditions are intensive, with a high risk of mechanical damage to the cabin walls.

-

There are no electrostatic problems and colour changes are rare - no need for plastic structures.

-

The customer expects durability, ease of use and low running costs.

Estimated effectiveness:

Impact- and wear-resistant steel construction for multi-shift operation

No need for frequent repairs and maintenance, savings of 30-50% per year over more delicate solutions

Rigid construction guarantees consistent application conditions under heavy loads

With reproducible colours and batches, minimal powder loss and less need for cleaning

Proposed solution:

In a company involved in the production of metal structures in short runs, various options were considered, including a tunnel cabin to ensure a continuous flow of parts. However, an analysis of the process showed that with frequent interruptions and no permanent operator, the investment in a more expensive, semi-automated solution would not be justified. The choice was therefore made for a classic powder booth with a steel construction.

The lack of the need to eliminate electrostatic charges made it possible to use carbon steel - durable, impact-resistant and easy to maintain. This reduced costs while providing a solid base for intensive work. The cabin was fitted with a dust collector with filters adapted to the large amount of dust, and the ventilation system was optimised for long shifts.

The rigid steel construction also enabled the use of a quick-cleaning system and additional fixings. The result is an easy-to-use, durable workplace that can withstand intensive use - sufficient where the rhythm of production does not yet justify the investment in a tunnel cabin.

Technologies used

Check also:

Products used in this case study