Made in Romer

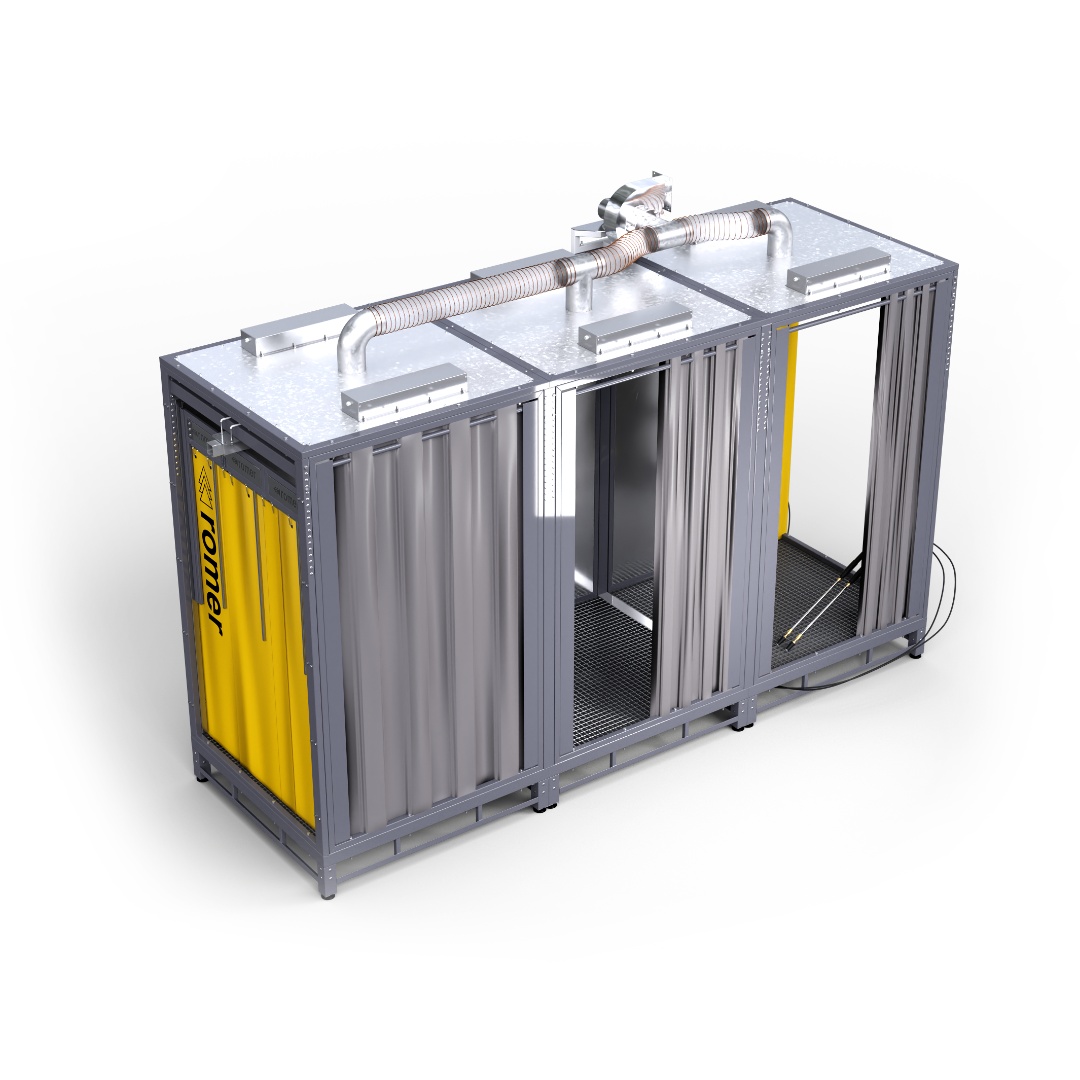

Pressure washer

Bottom tank made of chemical-resistant plastic, equipped with a simple grease and sediment separator. Facilitates the disposal of used liquid and protects the system against clogging. Capacity: 25 litres.

Models

MS-1515

MS-1515

- Working dimensions: W1500 D1500, External dimensions: W2100 D1600

MS-3015

MS-3015

- Working dimensions: W3000 D1500, External dimensions: W3600 D1600

MS-4515

MS-4515

- Working dimensions: W4500 D1500, External dimensions: W5100 D1600

MS-6015

MS-6015

- Working dimensions: W6000 D1500, External dimensions: W6600 D1600

MS-7515

MS-7515

- Working dimensions: W7500 D1500, External dimensions: W8100 D1600

MS-3030

MS-3030

- Working dimensions: W3000 D3000, External dimensions: W3600 D3100

MS-4530

MS-4530

- Working dimensions: W4500 D3000, External dimensions: W5100 D3100

MS-6030

MS-6030

- Working dimensions: W6000 D3000, External dimensions: W6600 D3100

MS-7530

MS-7530

- Working dimensions: W7500 D3000, External dimensions: W8100 D3100

MS-9030

MS-9030

- Working dimensions: W9000 D3000, External dimensions: W9600 D3100

MS-CUSTOM

Custom

- Dimensions: your dimension

Common parameters:

- Rated power: 11kW.

- Chemistry pressure: less than or equal to 20 Bar

- Water pressure: less than or equal to 200 Bar

Benefits for you

Intelligent control and automation of operations

The 4-inch colour touch panel provides convenient access to all the most important settings of the washer. The system allows you to save your own programmes, which is particularly useful for more demanding processes. The function for estimating the energy consumption of pumps and heaters enables cost control and better work planning. In addition, a built-in calendar allows you to programme the automatic start of tank heating at specific times of the working days.

Liquid agitation protection and emergency status memory

To prevent liquids from the different stages of washing from mixing, the washer is equipped with separate return pumps and independent plumbing within the pump table. In addition, in the event of a sudden power failure, the system uses an internal physical memory that operates without voltage. It ensures that when the unit is restarted, it continues operation from the point of interruption, preventing unwanted mixing of media between tanks.

Modular design with flexible equipment

The pressure washer has been designed as a fully modular solution that can be easily extended with additional length or width segments, without the need to interfere with the existing structure. The system also allows components such as walls, doors or rails to be retrofitted at any time during operation. As part of this flexibility, the user is free to set up accessories - such as a lance rack mounted at the desired location on the worktop - allowing the layout to be tailored to individual preferences. The top is made of high-quality stainless steel to ensure durability and corrosion resistance, supporting the long-term use of the system.

Multi-stage spray filtration

To ensure efficient and safe operation, each wash top is fitted with an acid-resistant pre-filter, which stops larger contaminants from entering the downstream stages of the circuit. In addition, a fine filter with a see-through body is used in the chemical wash stage circuit, allowing the operator to constantly check the cleanliness of the liquid and effectively separate fine particles.

Saving time, energy and investment costs

The pressure washer is a cost-effective solution that combines high efficiency with relatively low operating and investment costs. Thanks to its small tank capacity, the unit quickly reaches operational readiness, which translates into lower standby energy consumption. The high operating pressure acts as an additional mechanical factor, reducing the consumption of chemicals, energy and operator time. The open design of the washer allows for convenient washing of large, unique parts with difficult access, without investing in costly tunnel or chamber systems. It is a practical choice for companies looking for a flexible yet cost-effective solution for surface preparation.

Integration with external systems and flexible control

The washer allows the creation of customised, extensive automation systems thanks to programmable relay outputs that can be tailored to specific events and user needs. Built-in RS485 ModBus communication allows full control of the unit from master systems and integration with customer infrastructure such as CRM or ERP. Once connected to the network, real-time monitoring of operating parameters, energy consumption or temperatures is possible.

Washing steps

Steps in the washing process

- Phase 1 - Washing. In the first phase, a basic cleaning of the surface takes place to remove dirt, grease and other contaminants using appropriate chemicals.

- Phase 2 - Rinsing. The second step is to rinse chemical residues and dirt from the surface with technical water, which prepares the component for the final stage.

- Phase 3 - DI rinse. The final - optional - phase is the DI rinse, designed to remove all mineral traces and ensure a perfectly clean surface without streaks.

Closed loop and high pressure cleaning

The washing process is carried out in a completely closed circuit, which makes it different from standard solutions. All components have been selected in such a way that they are not damaged when liquid containing solids or aggressive chemicals is fed back in. Unlike typical washers, which can fail under such conditions, the components used are fully designed for this. Additional effectiveness is provided by an operating pressure of up to 200 bar, which is an important mechanical factor in helping to remove dirt.

Robust tools and a pump resistant to working conditions

The rotary nozzle, thanks to the rotating movement of the water jet, effectively removes dirt, even from hard-to-reach areas. This solution saves time and effort for the operator while increasing cleaning efficiency. The system is complemented by a gun suitable for temperatures up to 150°C and a reinforced hose with resistance up to 300 bar. The gun's perforated handle effectively dissipates heat, protecting the user's hands. The whole system is supported by an acid-resistant, several-stage high-pressure pump, responsible for reliable feeding of high-temperature chemicals over many years of operation.

Flushing (ordinary and DI)

The flushing procedure can be a completely closed circuit, if the procedure is equipped with an additional large-capacity tank into which the liquid is discharged.

Infinitely variable pressure control (normal and DI)

As 200 bar is a very high pressure, which can damage delicate materials, the washer has an infinitely variable regulation of the pressure applied so that the pressure can be perfectly adjusted.

High-pressure pump with ceramic pistons (normal and DI)

A high-quality pump equipped with hard ceramic pistons is the heart of the flushing system, one of the best solutions available on the market. It provides very high pressure and high flow, with relatively low power - 4kW. Fitted with the best Parker seals, the pump ensures a long service life.

Reverse osmosis station - DI rinsing (optional)

The reverse osmosis station is an additional component - necessary to produce the demineralised water needed for the third, optional treatment.

Flushing with demineralised water (optional)

The demineralised water rinsing procedure is the icing on the cake of any surface preparation process, removing residual salt from the surface and ensuring the required adhesion.

In our shop

Technologies used

Video

This video requires 'Tracking and Performance' consent.

Gallery