The heart of

ProfiSpray V

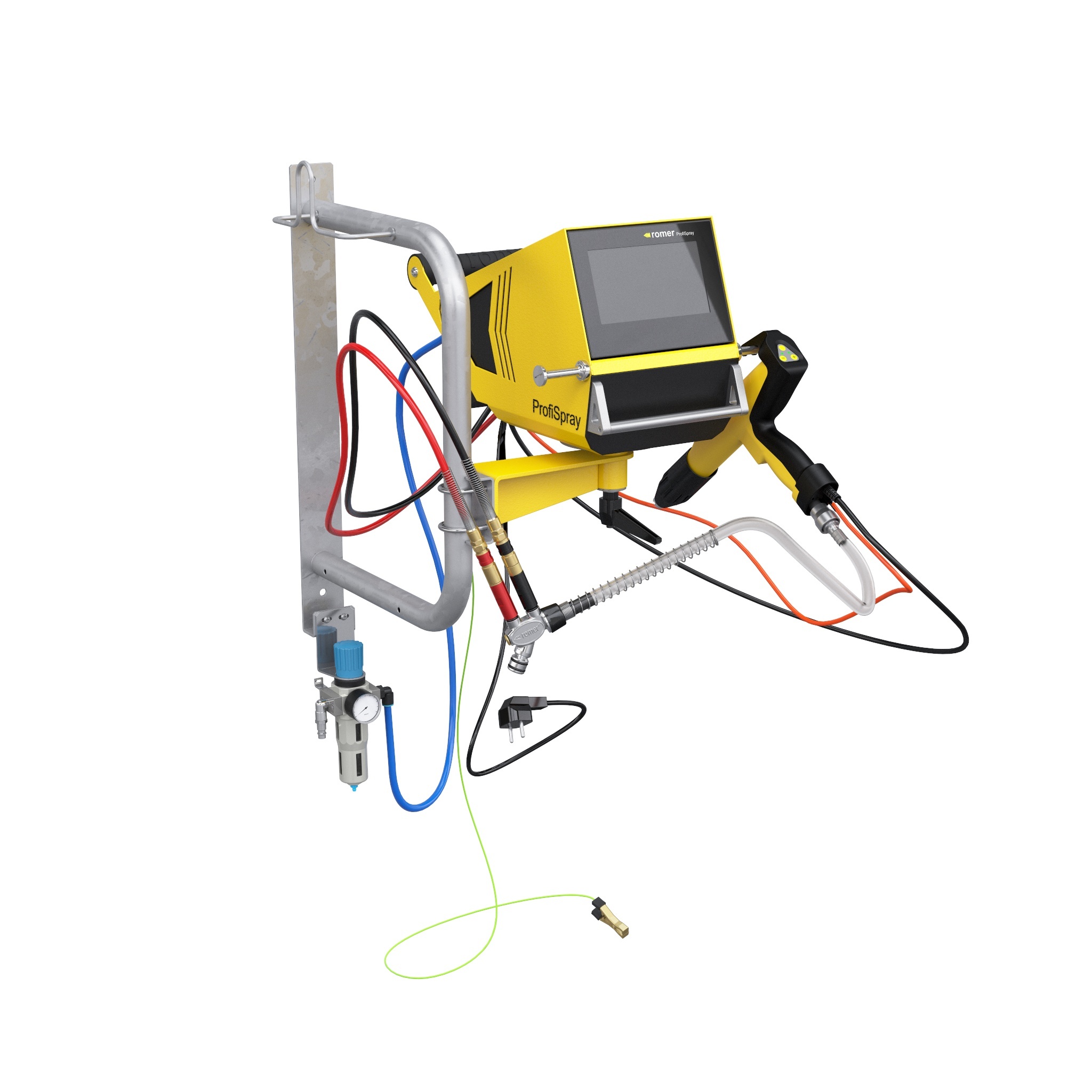

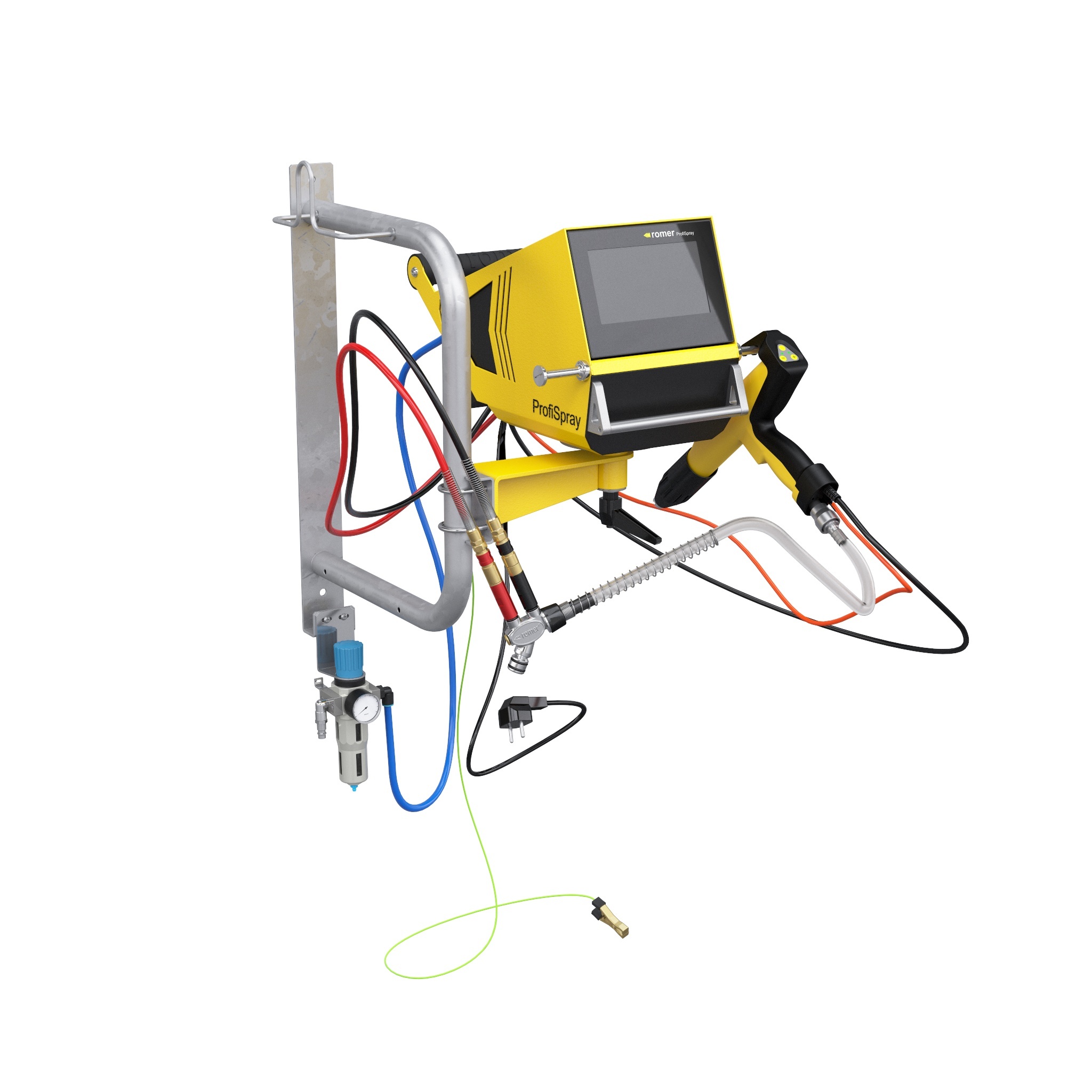

The new ROMER ProfiSpray V applicator is distinguished by its intuitive 7" display with a prompting system, making work easier even for inexperienced users, and practical features such as a gun holder, accessory drawer and quick colour change from cardboard.

Made in Romer

ProfiSpray V

Bottom tank made of chemical-resistant plastic, equipped with a simple grease and sediment separator. Facilitates the disposal of used liquid and protects the system against clogging. Capacity: 25 litres.

Models

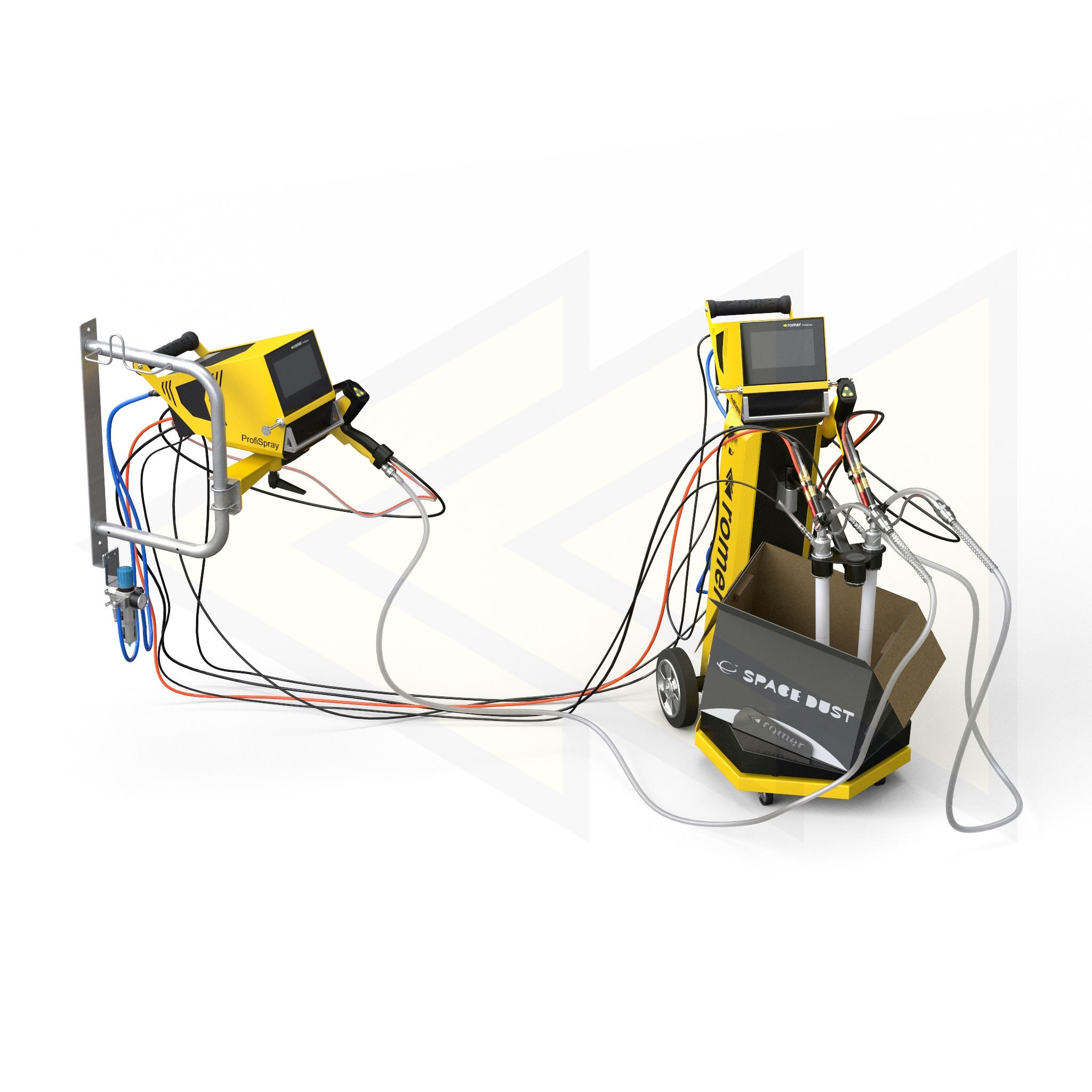

ProfiSpray V

New generation applicator

ProfiSpray H

Ergonomics in continuous processes

ProfiSpray Base

Version for automatic cabins

ProfiSpray A

For automatic paint shops

Benefits for you

Touch panel

ROMER applicators feature state-of-the-art 7" colour touchscreens for intuitive operation, even when wearing work gloves. The device offers three standard operating modes - for flat surfaces, hard-to-reach surfaces and repainting - as well as the possibility to configure individual modes to suit specific user applications. The system allows naming of programmes, and precise control is provided by graduations of 0.1 kV and 0.1 µA over the full control range. The use of advanced pneumatic valves (patent pending) allows precise air dose management, and actual flow measurement immediately detects anomalies such as pressure drops or obstructions in the system. The unit also offers extensive diagnostic tools and the ability to integrate with superordinate systems via the ModBus protocol.

ProfiGun PM-1 pistol

The ROMER gun is a lightweight, ergonomic tool with excellent balance and a contoured, conductive handle that provides a secure grip and effective grounding for the painter. The handle houses the intuitive controls - adjusting the proportion of paint and changing programmes - without having to stop working. A ceramic cascade with up to 100,000 volts (negative polarity) effectively charges any type of powder, and a new generation of nozzles enables precise coverage of even the most complex shapes. The gun is made of impact-resistant materials and its demountable design with a replaceable powder tube makes maintenance easy. The model is covered by a patent in the EU and the USA.

Cascade repeater with up to 100,000 volts of charge

The high-precision product is capable of ejecting ions up to 17,000 times per second, ensuring more accurate and reliable paint deposition on the workpiece.

ProfiJector powder paint pump

The new, efficient injector design provides an effective feed angle, which translates into savings in both ink and air - compared to traditional right-angle injectors. The injector is the subject of a European patent

ROMER ProfiCharge

The current can be precisely adjusted even below 10 μA - the adjustment range starts from 0 μA to 100 μA. The ProfiCharge system operates in the 0-10 μA range, with an accuracy of 0.1 μA.

Automatic gun cleaning function

For fast and accurate colour changes, an automatic gun purge function has been developed. It can be activated from the handle or screen - the gun is cycled with compressed air, making it easier to keep clean and minimising the risk of contamination during colour changes.

Specially developed grounding handle for the operator

Safety is our top priority - which is why, in hazardous areas, it is crucial to ensure proper earthing. The gun's handle has been fitted with special carbon fibres to effectively ground the operator during operation.

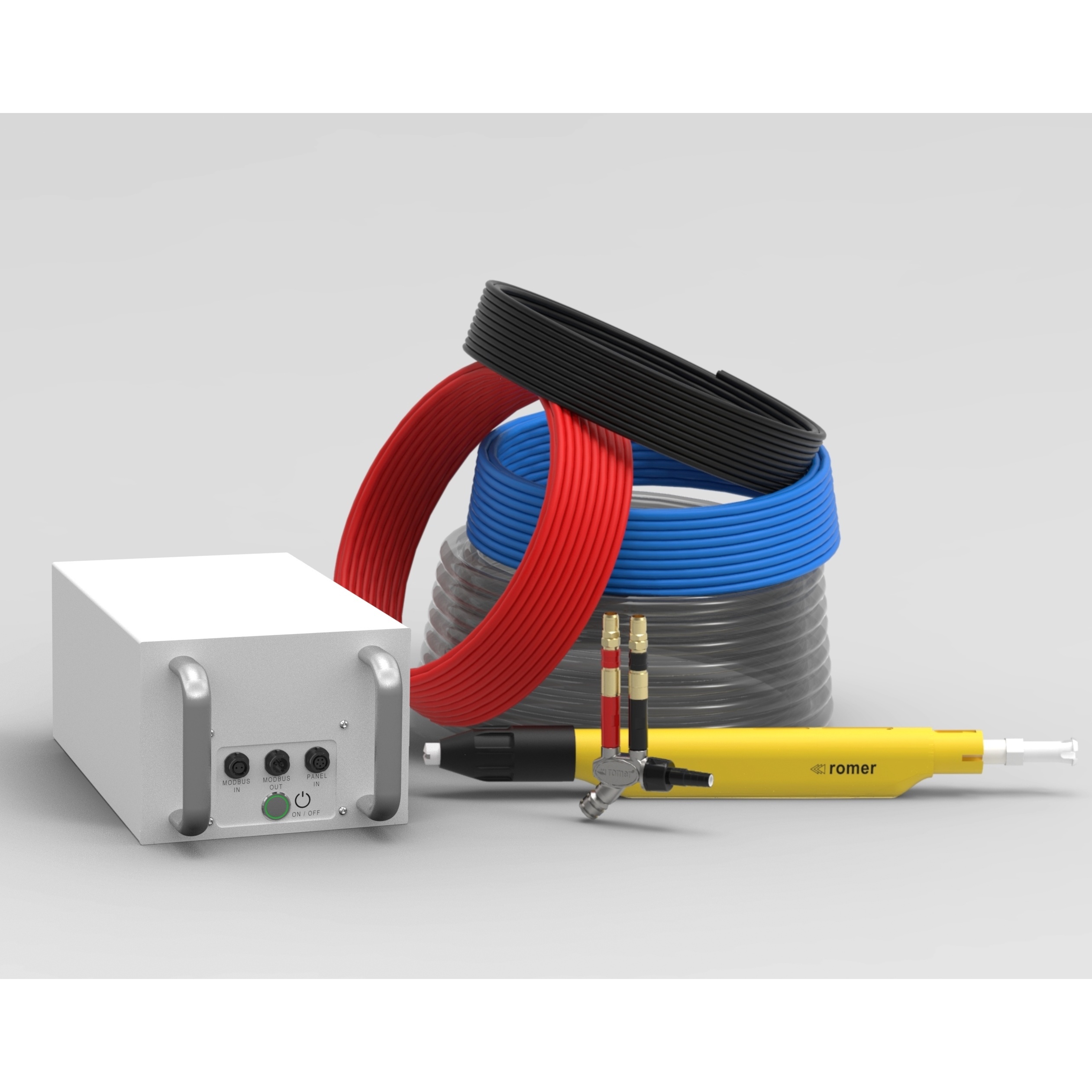

Anti-static hose with double grounding strap

The anti-static hose is equipped with a double grounding strap - an additional strap, in addition to the standard one, effectively neutralises electrostatic charges accumulated during paint transport, increasing process safety and stability.

Powder path in the gun without unnecessary connections

The ProfiGun gun has been designed so that the powder tube - from the quick coupler to the nozzle itself - is made from a single piece. The absence of joints and elbows eliminates the risk of leakage, improving reliability and making maintenance easier.

Precise air dosage (patent pending)

With the electronically controlled needle valves developed by Romer, air delivery is even more precise. This is made possible by the use of specially developed integrated flow meters that respond to changes in real time.

Nozzles made of high-quality polymer

The nozzles have been made from materials that are resistant to electrical punctures and at the same time materials that do not adhere to the powder paint. As a result, they are resistant to clogging, and cleaning them during colour changes is quick and easy.A slot nozzle cap is included as standard with each application kit, allowing the gap clearance to be reduced, making it possible to correct the spreading between 30° and 50°

Unit diagnostics

The unit continuously monitors all key parameters necessary for trouble-free operation and long system life. The system records a complete history of faults, errors and possible service suggestions, facilitating diagnostics and preventing failures.Full job history with data such as, job name, start and end dates, ink used, and duration of individual operations. Check the statistical data in the daily report.

Visual component wear counters

The system monitors the wear and tear of key components such as: - injector cartridge, - gun nozzles, - powder hose, as well as recording the time since the last start-up and the total operating time of the machine. All data is presented in the form of easy-to-read visual counters, making it easy to schedule servicing and replacements.

Professional mode

Are you already a professional? If not, we’ve prepared helpful tips to guide you as you begin your journey with powder coating. When the set parameters or your actions suggest that you might be making a mistake, on-screen messages will point you in the right direction. However, if you are already experienced, in this mode the tips will be disabled, allowing you to work without additional prompts. We won’t get in your way.

Animated troubleshooting module

Do you have a problem with your application technology, and can't diagnose it? is it spitting paint, or is it pulsating? don't know what is causing it? this animated module will guide you step by step through the diagnosis procedure and allow you to understand and rectify the problem.

Management of orders

Do you want to know exactly how long a job took? How much paint did you use? Or exactly how much time did the painting process itself take and how much time did the other processes take? This function is for you.

Intelligent control and advanced statistics

The ProfiSpray system offers extensive but intuitive controls that adapt to the needs of beginners and professionals alike. The user has access to a list of pre-programmed settings with names, can quickly switch between programmes thanks to the "handy programme" function and can track component wear using visual counters. The availability of up to eight languages makes operation user-friendly for any operator. In addition, an animated diagnostics module helps to solve the most common problems with the powder application step by step. Advanced statistical functions - both daily and for entire jobs - enable accurate accounting of working time, ink consumption and the efficiency of the entire process.

Quick gun change (QuickSwap)

QuickSwap versions allow the entire gun to be changed in an instant without tools - via an integrated quick release guide. This significantly reduces production downtime and streamlines colour changes.

Various spray tips

Interchangeable conical, flat, diffusion nozzles and specialised spray tips are available. This allows the ideal powder jet to be selected to suit the type of workpiece and the desired coating effect.

Integrated high voltage (HV) module

Each ProfiSpray gun has a built-in HV module that generates electrostatic voltage without the need for external generators. This simplifies installation and increases system reliability.

In our shop

Customer feedback

Video

This video requires 'Tracking and Performance' consent.

Gallery