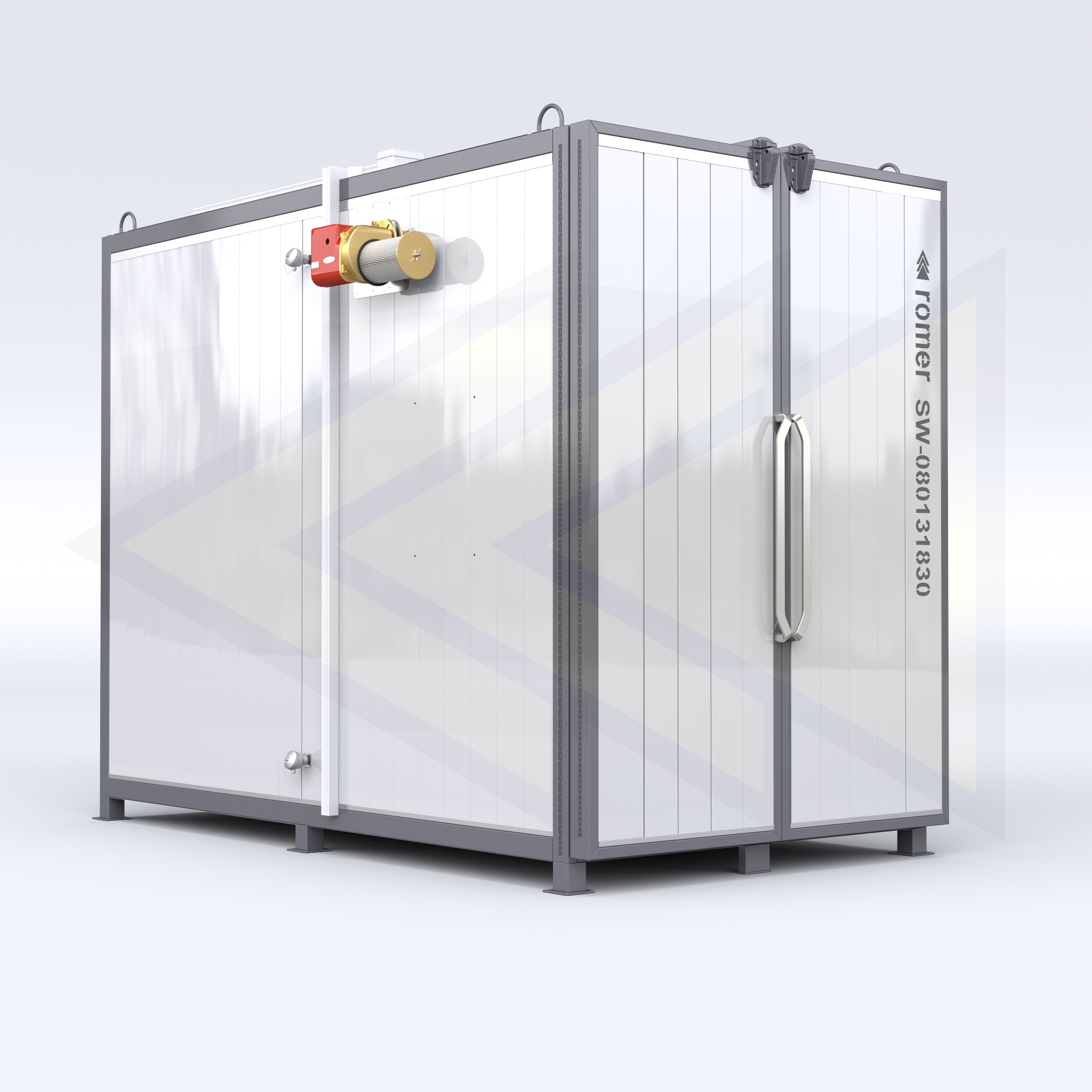

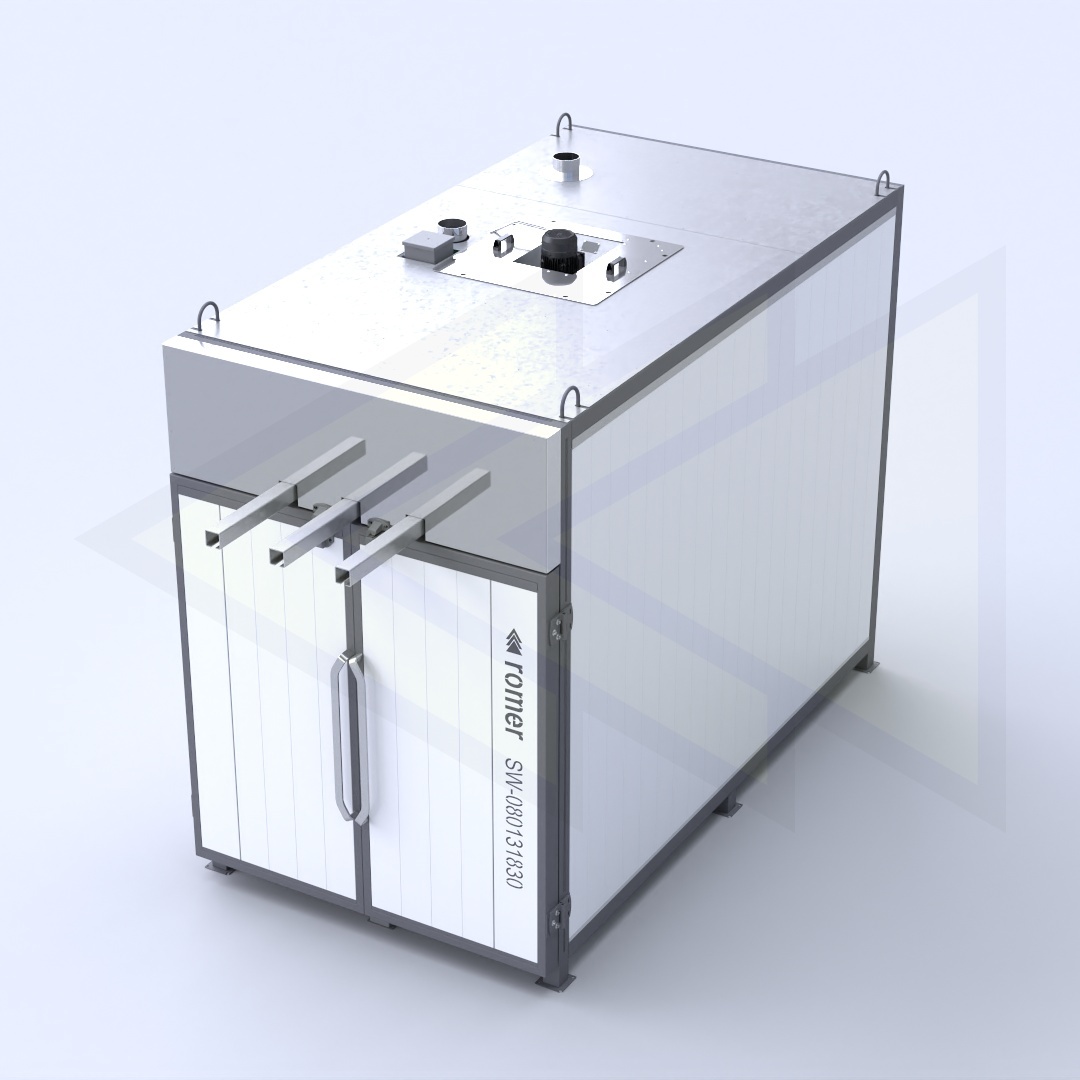

Romer technologies

Advanced control | MTS multi-point temperature measurement system

MTS - Multipoint Temperature Measurement System

MTS is an advanced inspection system based on multiple measurement points. Unlike traditional methods, which rely on a single sensor, MTS uses a set of independent sensors located at strategic points in the chamber. This allows a complete picture of temperature conditions to be captured - both in the centre and at the periphery of the workspace. The system allows more accurate process control, faster detection of anomalies and precise real-time temperature management.

ROMER MTS (Two and more sensors)

In ROMER ovens, the MTS system is based on multi-point temperature measurement, where at least two sensors are used, and in practice often more - depending on the oven configuration. This arrangement gives a more complete and reliable picture of the heat distribution in the chamber. This makes the heating and firing process more stable and minimises the risk of measurement errors. The result is greater measurement reliability, process safety and the ability to better match the kiln's operating parameters to the specifics of production.

Oven without MTS (One sensor)

Traditional solutions are limited to a single measuring point. This means that the temperature value recorded does not reflect the actual conditions in the entire chamber - it can be distorted by local variations or uneven heat distribution. As a result, process control is less precise, the risk of errors increases and it is more difficult to ensure reproducible firing quality.

Check also:

Products in which the technology has been used