Romer technologies

Application automation | workpiece measurement gateway and detection systems

Use of a single photocell

The use of a single photocell in the workpiece space allows the length of the workpiece to be measured and thus gives the possibility to switch on the guns when the workpiece comes within their range, and to switch off the guns immediately after the workpiece is painted. A photocell is included as standard.

Identification of workpieces with special markers

Identification tags can be placed on the workpieces. On the basis of these, a PLC controller in combination with a photocell recognises the workpiece to be painted and switches the guns on and off in good time - thus saving energy and powder paint.

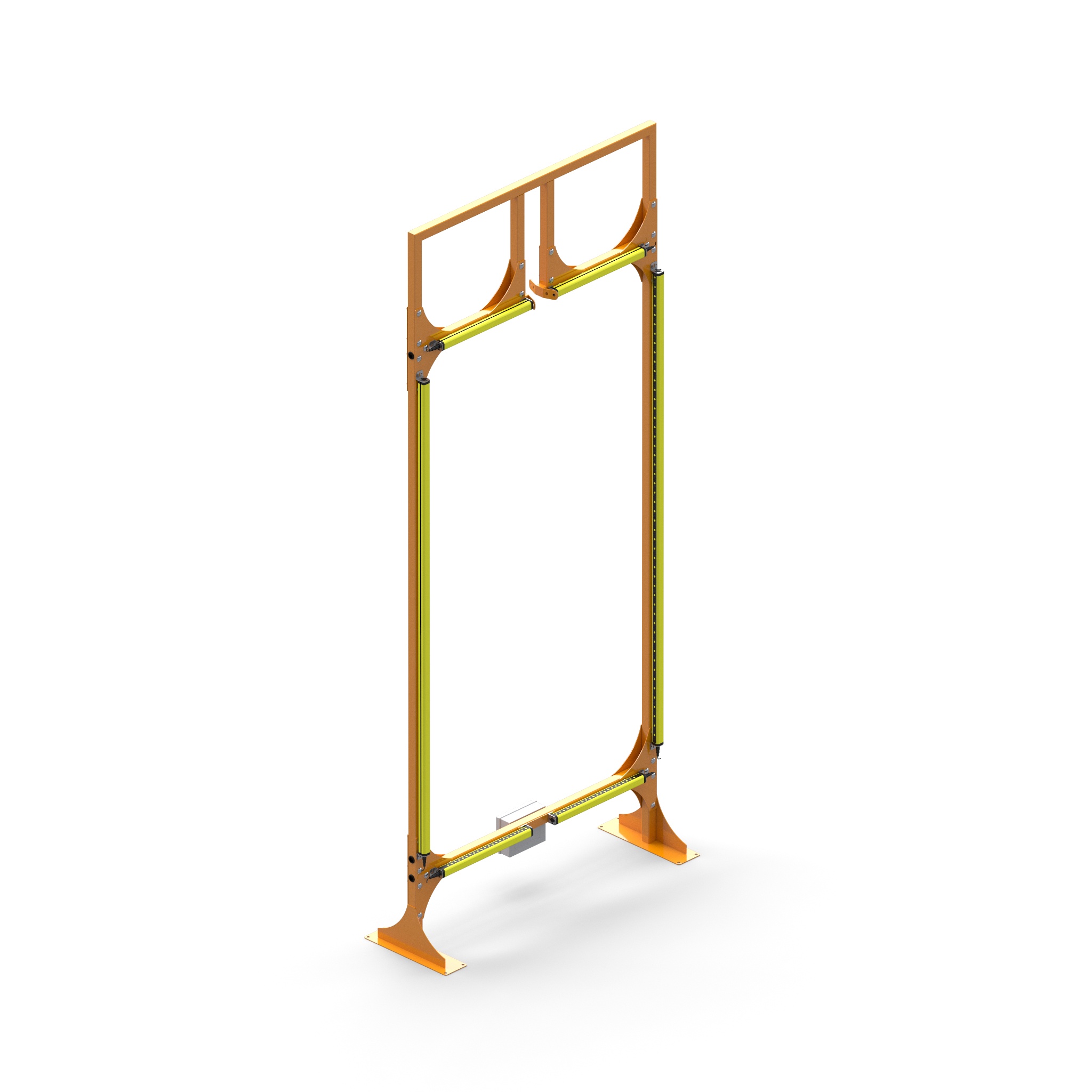

Vertical workpiece shape detection

The use of light gates with detectors horizontally, allows the PLC controller to analyse the vertical shape of the workpiece. The PLC counts the time at which the workpiece should appear in the gun space - this makes it possible to selectively switch the guns on or off.

Use of light gates with multiple sensors horizontally and vertically

This solution allows the precise measurement of workpiece dimensions, which also makes it possible to control manipulators.

Benefits of gates and photocells

Saves powder and energy. Elimination of painting a zone where there is no workpiece. Precise gun control using light gates.

Check also:

Products in which the technology has been used