Romer technologies

Thermal insulation | glass or ceramic wool

Glass wool

Glass wool is a proven standard insulation material commonly used in industrial ovens. Its greatest advantage is the excellent balance between insulation efficiency and cost - making it very economical. It retains heat perfectly, which translates into energy savings and temperature stability in the oven chamber. Glass wool is also relatively easy to install and resistant to most typical operating conditions, making it a versatile choice for many applications where temperatures do not exceed very high values.

Ceramic wool

Ceramic wool is an insulation material designed for ovens operating at very high temperatures, where standard glass wool is not sufficient. Thanks to its exceptional resistance to high temperatures and thermal shocks, it provides excellent insulation even in demanding conditions. Although it is considerably more expensive than glass wool, its use makes it possible to achieve greater energy efficiency and safety in ovens with higher thermal performance. It is a cost-effective investment where durability and reliability are required for intense heat loads.

Check also:

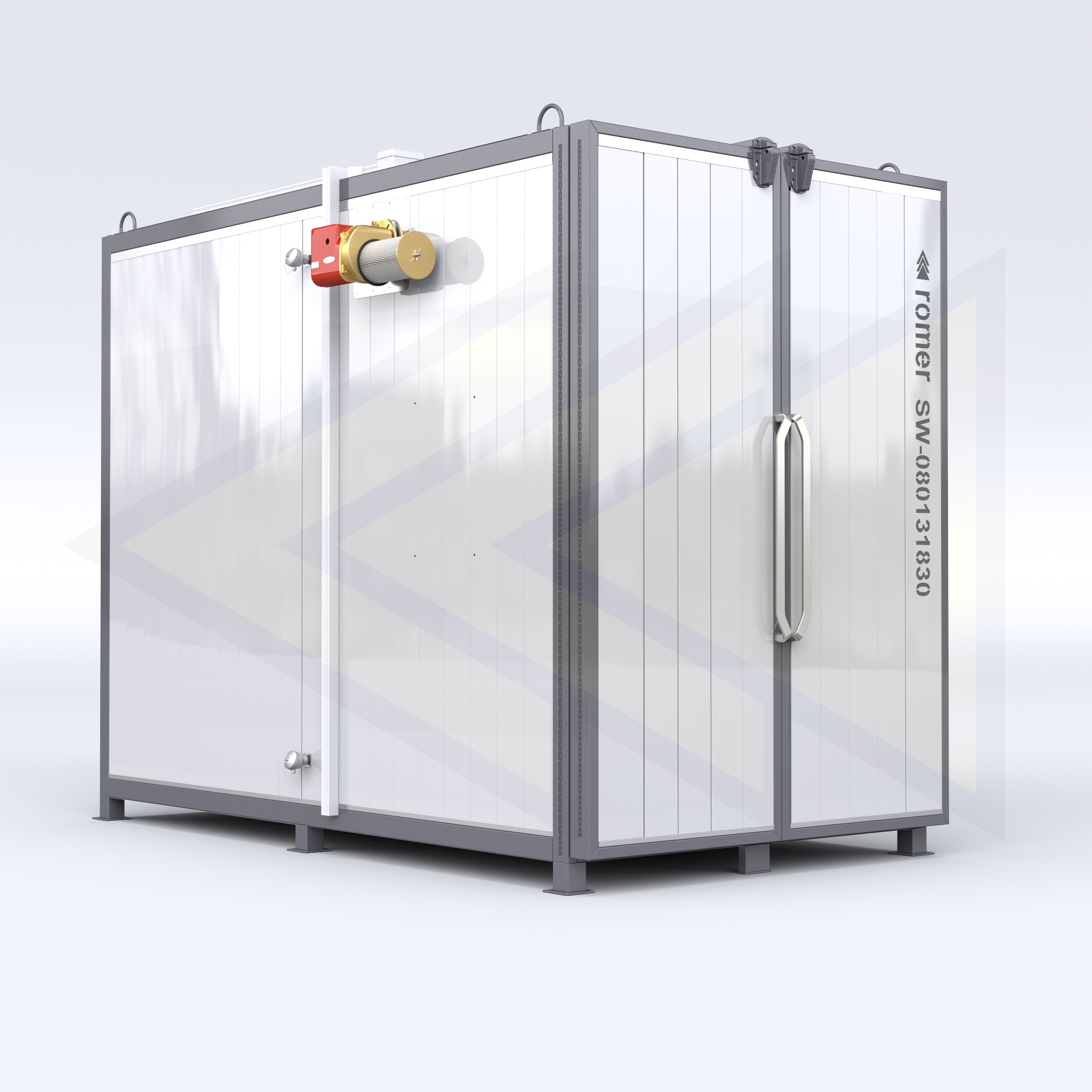

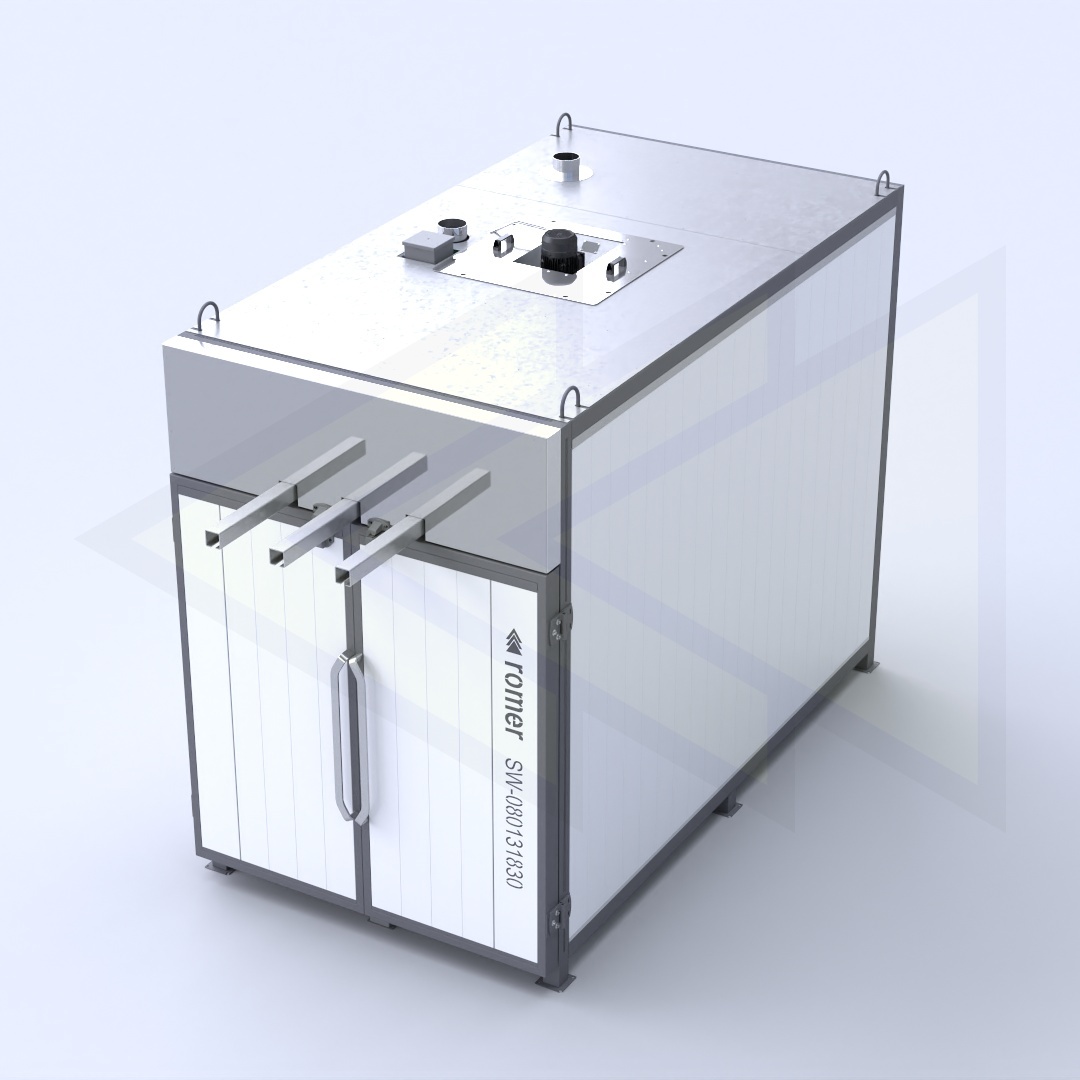

Products in which the technology has been used