Romer technologies

Zone control | Multi Zone Heat system

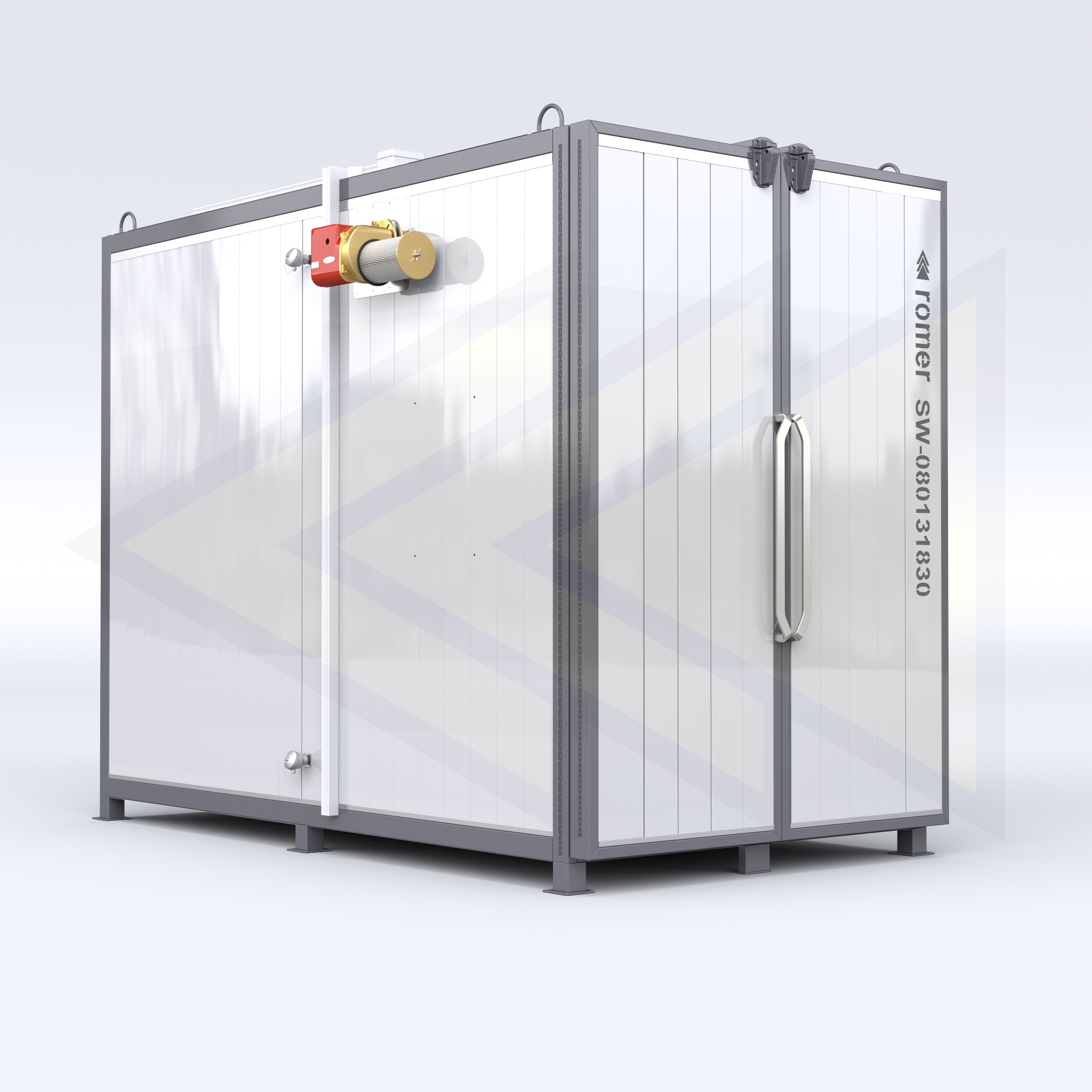

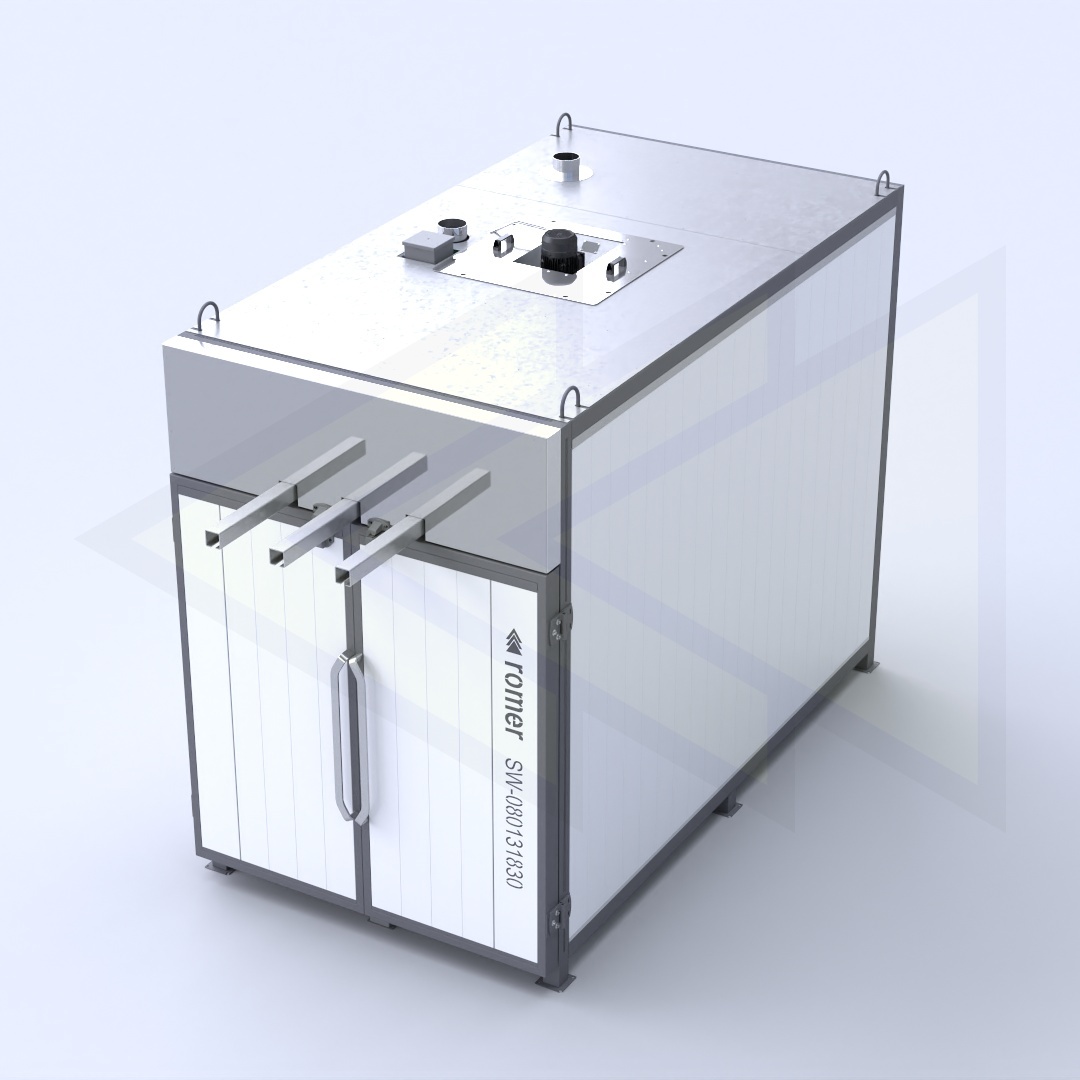

Multi Zone Heat

The Multi Zone Heat system is a state-of-the-art solution that allows precise control of the oven temperature by dividing the chamber into multiple independent heating zones. Each zone is monitored by a set of sensors that detect and compensate for temperature differences in real time. This makes the firing process stable and the conditions uniform - even for workpieces with varying material thicknesses. The result is higher quality, greater repeatability and the elimination of overheating or underheating problems.

Oven with MZH (4 zones, 12 sensors)

The Multi Zone Heat system allows up to 8 independent heating zones to be operated in one oven, with three temperature sensors per zone. In ROMER ovens, a configuration with 4 zones is available, giving 12 measuring points in the entire chamber. Thanks to this solution, the process is constantly controlled and stabilised - temperature differences are immediately detected and compensated for, guaranteeing the highest firing quality and repeatability.

Normal oven (1 zone, 1 sensor)

Traditional ovens have only one heating zone and one temperature sensor. This means that the heat distribution inside the chamber cannot be accurately controlled. Temperature differences between different areas are not captured or equalised, which can lead to uneven firing of workpieces. Consequently, there is a risk of overheating thinner parts or underheating thicker parts, which reduces the quality of the final product.

Check also:

Products in which the technology has been used