|

Aluminum fans |

The volume is only 79dB |

|

|

Automatic cleaning |

A new better method |

|

|

Filters 100% polyester |

Tight assembly |

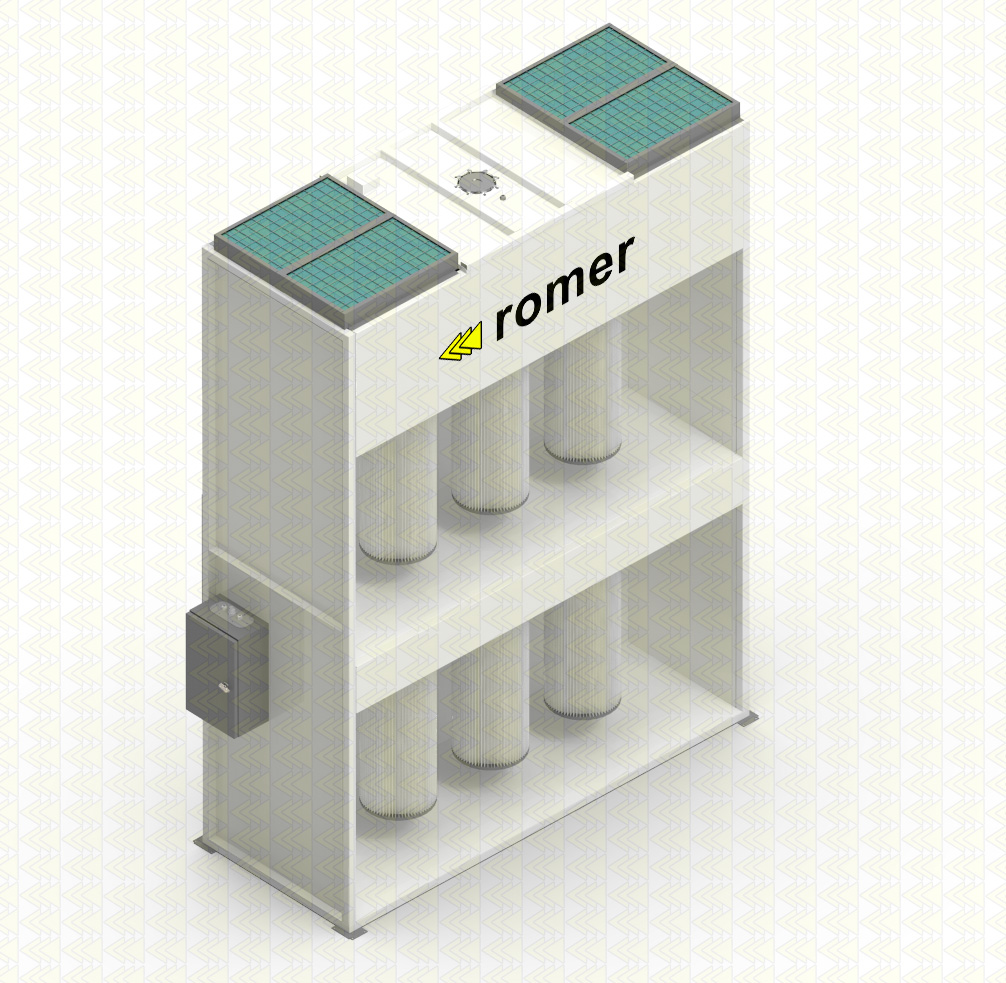

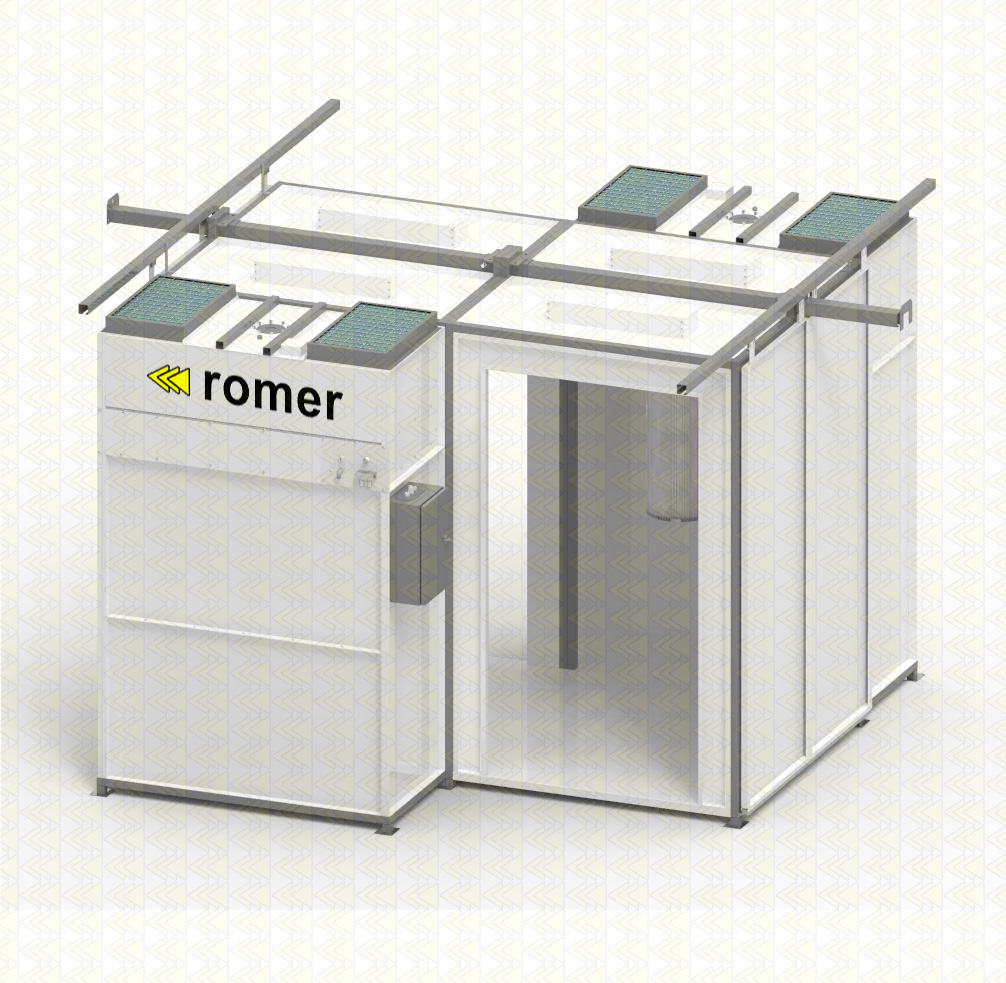

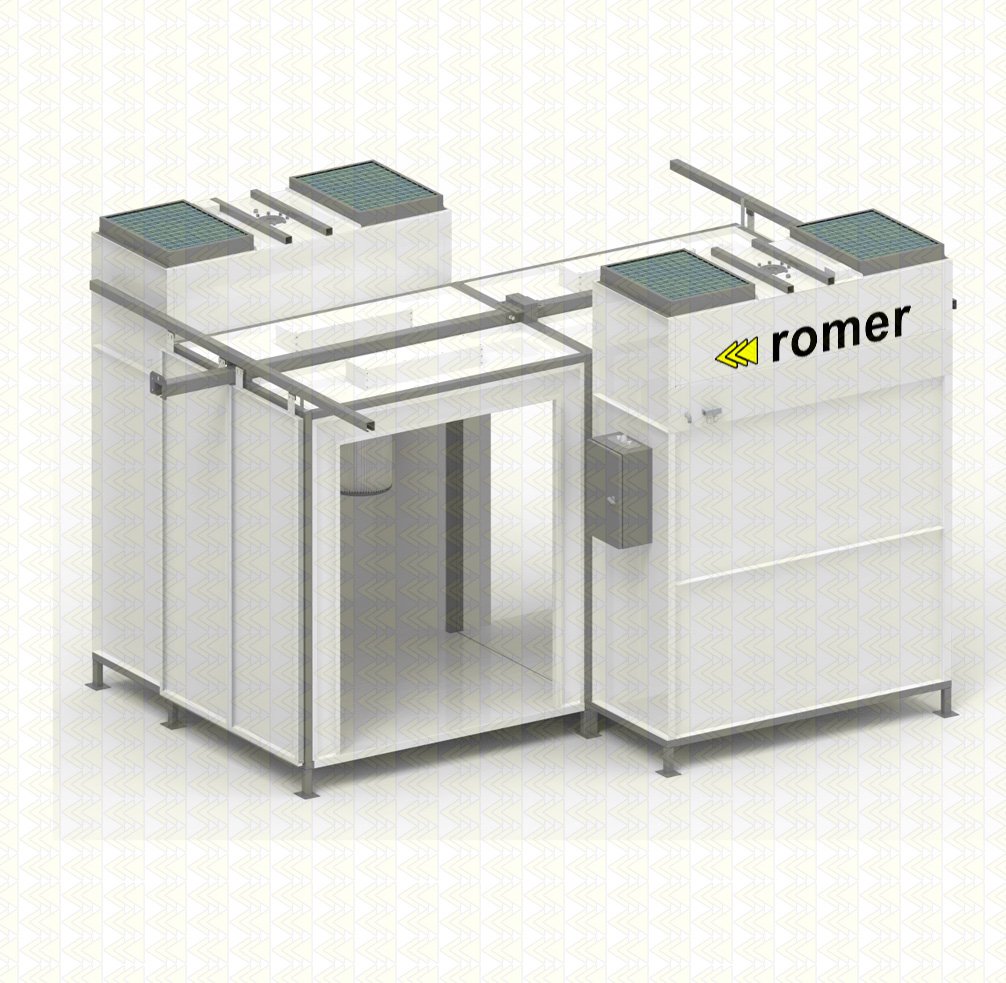

Standard models

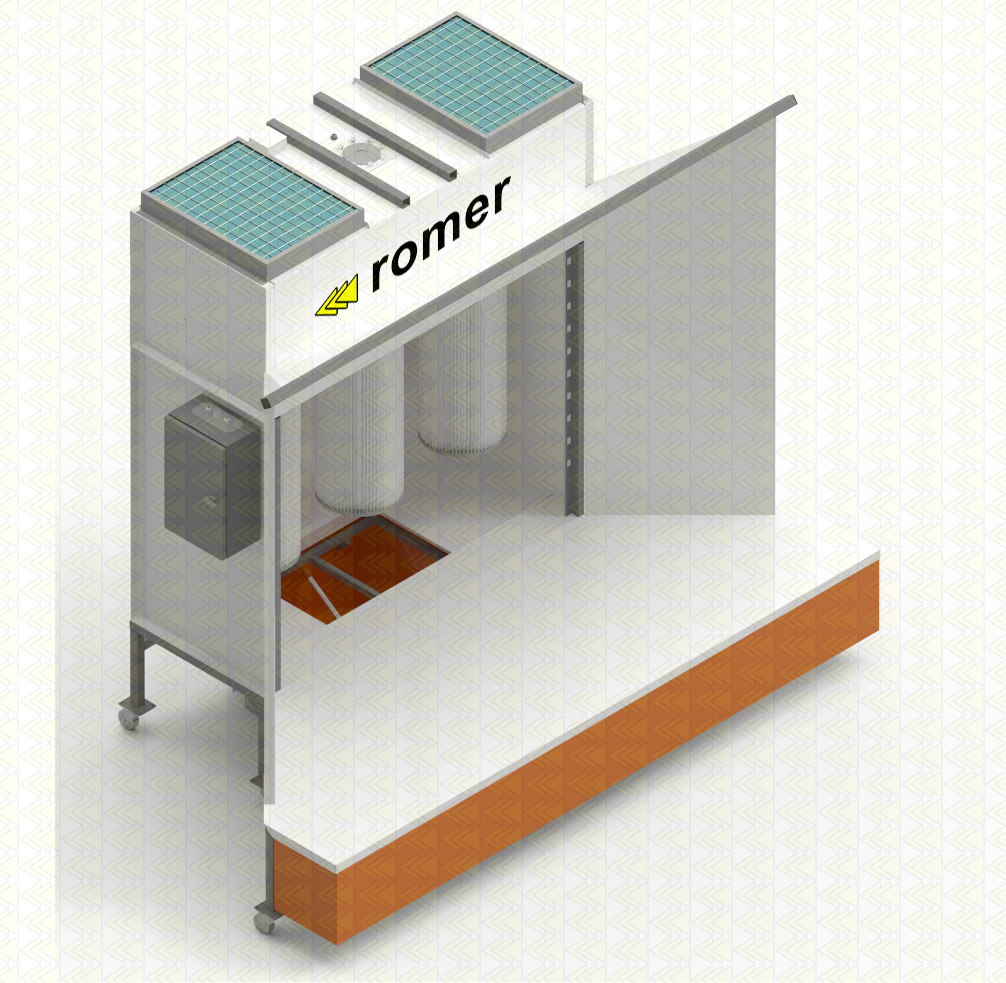

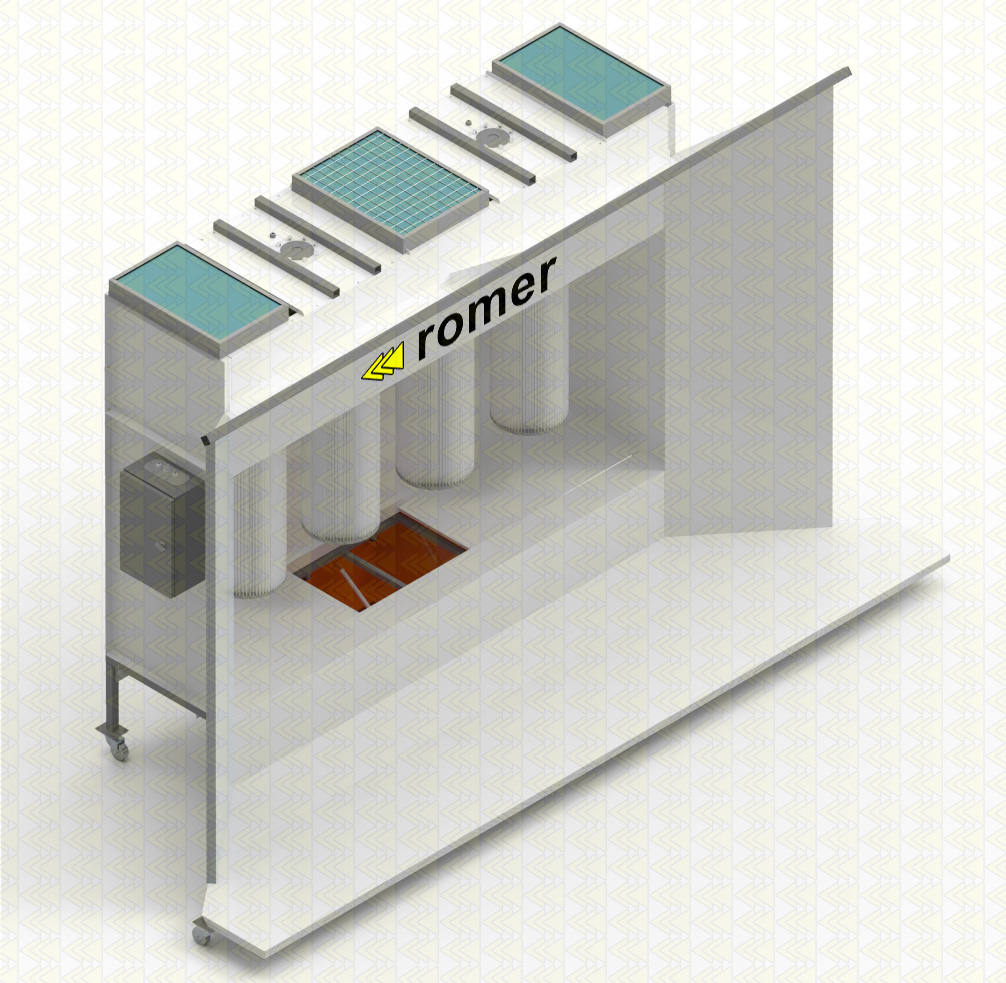

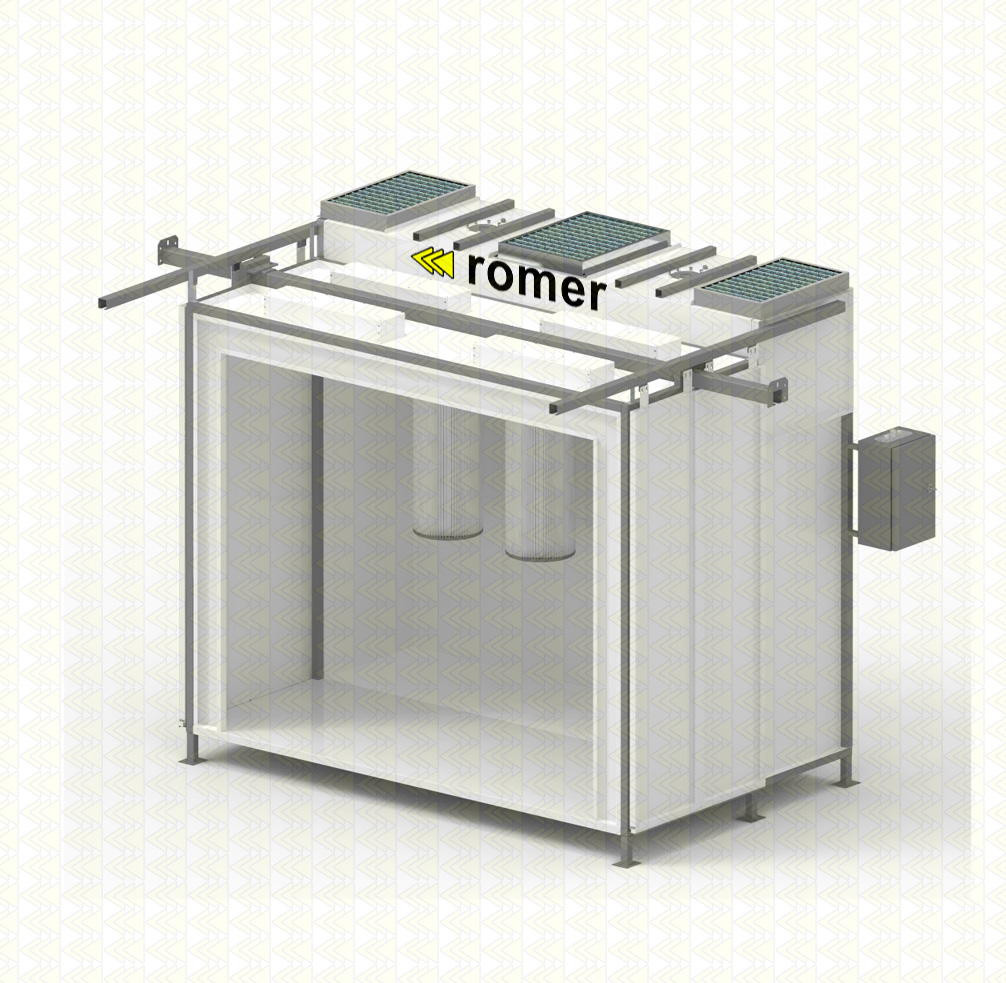

| Cab model |

Operator window dimension (mm) |

Dimension |

Windows |

Power (kW) | area filtration | max. powder output | Filter clogging sensor | Lowered top |

Tank, fluidization sifter |

Drive beam drive |

| KPZ-1 | 800x1300 | none | 1 | 0.69kW | 15m2 | 400g/min | ? | option | option | option |

| KPZ-2 | 1400x1800 | none | 1 | 2.2kW | 30m2 | 400g/min | ? | option | option | option |

| KPZ-3 | 1600x1800 | none | 1 | 2.2kW | 45m2 | 400g/min | ? | option | option | option |

| KPZ-4 | 2000x1800 | none | 1 | 4.4kW | 60m2 | 400g/min | ? | option | option | option |

| KPO-2 | 2000x1800 | none | 1 | 2.2kW | 30m2 | 400g/min | ? | option | option | option |

| KPO-3 | 2800x1800 | none | 1 | 2.2kW | 45m2 | 400g/min | ? | option | option | option |

| KPO-4 | 4000x1800 | none | 1 | 4.4kW | 60m2 | 400g/min | ? | option | option | option |

| KPP-2 | 1200x1800 | 700x1800 | 1 | 2.2kW | 30m2 | 400g/min | ? | option | option | option |

| KPP-3 | 1400x1800 | 700x1800 | 1 | 2.2kW | 45m2 | 400g/min | ? | option | option | option |

| KPP-4 | 1 700x1800 | 700x1800 | 1 | 4.4kW | 60m2 | 400g/min | ? | option | option | option |

| KPD-2 | 1200x1800 | 700x1800 | 2 | 4.4kW | >=60m2 | 800g/min | ? | option | option | option |

| KPD-3 | 1400x1800 | 700x1800 | 2 | 4.4kW | >=90m2 | 800g/min | ? | option | option | option |

| KPD-4 | 1 700x1800 | 700x1800 | 2 | 8.8kW | >=120m2 | 800g/min | ? | option | option | option |

| These are examples of standard cabins - other dimensions, configurations, available on individual request. | ||||||||||

Comfort

|

Touch controls ROMER cabins are equipped with 4" color touch screens. Cabin operation is intuitive, it has 3 modes: automatic (timed), automatic (based on a clogged filter sensor), or manual. |

|

Filter clogging sensor A sensor is installed in the cabins that queues filters for cleaning when they become clogged. The system also informs you when the filters are exhausted |

|

|

Automatic filter cleaning The electronic system of automatic filter cleaning has a range of adjustment of cleaning frequency and firing time. Each filter is cleaned separately, the filters can also be cleaned manually using the buttons.

We know from experience that it is difficult for the operator to enforce filter cleaning. Thanks to this system, the operator will no longer have to think about it. |

|

Low volume Aluminum fans are very quiet, they work at the level of 74-79dB - It's not much. with the standard design of the cabin, it's even hard to talk. |

|

Security

|

Explosion-proof design The booths have been designed to prevent the formation of an explosive mixture during the painting process. Each component has been carefully selected to minimize this risk. |

|

Aluminum fans Aluminum fans are safe, they do not cause sparks when rubbing against metal elements - which in the case of a steel fan may cause an explosion. Thanks to their weight, they save energy and consume little electricity. At the same time, they are very quiet, working at the level of 74-79dB. The engine is hidden in the cab, which makes the cab lower. |

|

|

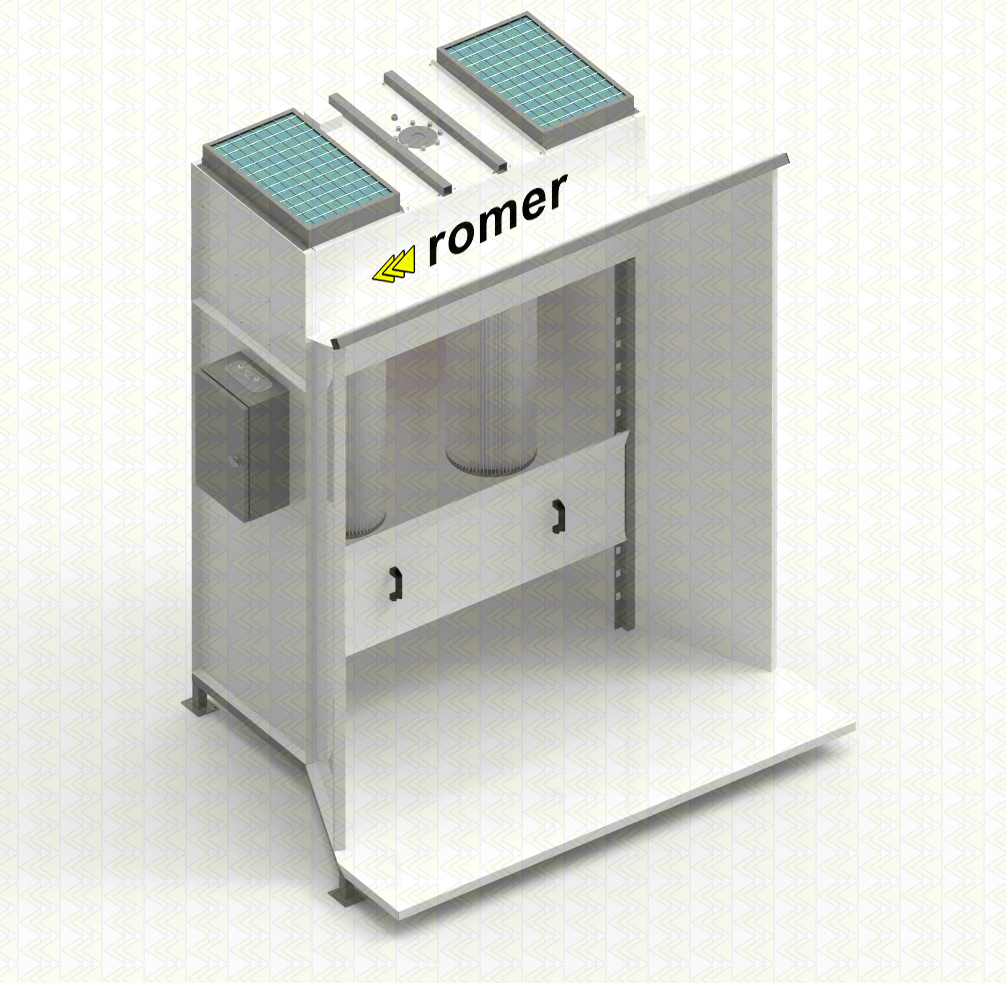

Tight assembly of filters Thanks to the use of mounting flanges, the assembly and disassembly of the filter becomes trivial. The screw tightening the gasket improves the tightness of the filter (compared to the bayonet filter), which increases the draft power of the cabin and improves the quality of filtration. |

|

Fire camera

option In accordance with the latest European standards, we install fire cameras. A sensor mounted in the cabin detects a fire within a fraction of a second and disconnects the power supply to the system. |

|

Quality

|

Adjustable draft An antistatic plate covering the filters is installed in the booth. It has, among other things, a protective function for the filters, stops the first wave of powder. In a well-designed booth, it improves the speed of air reaching the filters, flowing around the painted element. This facilitates the painting process itself, and also contributes significantly to improving the draft and thus the working conditions of the paint shop. The height of the hob can be adjusted on hinges. |

|

Low power consumption Thanks to the use of light steel alloys in the production process of our rotors, they have become extremely light. The fans need a small amount of electricity to rotate such a rotor, thus saving energy. |

|

|

Powder recovery By recycling materials, you save money, collect the powder from the booth and reuse it. The recovered powder should be sieved for reuse. |

|

Long filter life The thickness of the material from which our filter is made is 260g/m2 and the filtration surface (H900) is 15m2. For comparison, the standard used for the H900 is 160g/m2 at 7.5m2. This is the standard used in the most expensive automatic lines designed to move tons of paint.

There is an even cheaper type of filter, containing cellulose (paper) instead of polyester. |

|

ROMER JET?

The cabin is equipped with a tank - filter cleaning buffer. The pressurized air is released from the tank in a fraction of a second, then passing through the ROMER JET™ nozzle, it expands in the filter at high speed, exiting through the micro-holes in the filter, cleans it and the powder falls into the Booth.

Our ROMER JET™ system is patented, it cleans the entire filter from top to bottom, providing a unique cleaning effect, unattainable in the past (using a regular Jet-Venturi).

Additional options

|

Powder Tank

again In ROMER Booths, an optional powder tank can be installed. The tank can be mounted without fluidization equipped with pressure on pneumatic cylinders on the so-called garbage or a fluidized tank controlled by pneumatic cylinders with a screen. The fluidized tank is adapted to be connected to the Applicator and powder can be drawn directly from it. |

|

Screener In ROMER Cabins, an optional screen can be installed, provided that there is a tank in the Cabin. The sifter is necessary if the powder that has fallen into the hopper will be u rye for painting. The sifter allows you to get rid of impurities from the powder. The screen is powered by an electric vibrator designed for explosive zones. |

|

Cab Puller The cabin, by dragging the sling beams within the cabin, improves work efficiency, thus relieving the painter, who no longer has to move them manually. |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)