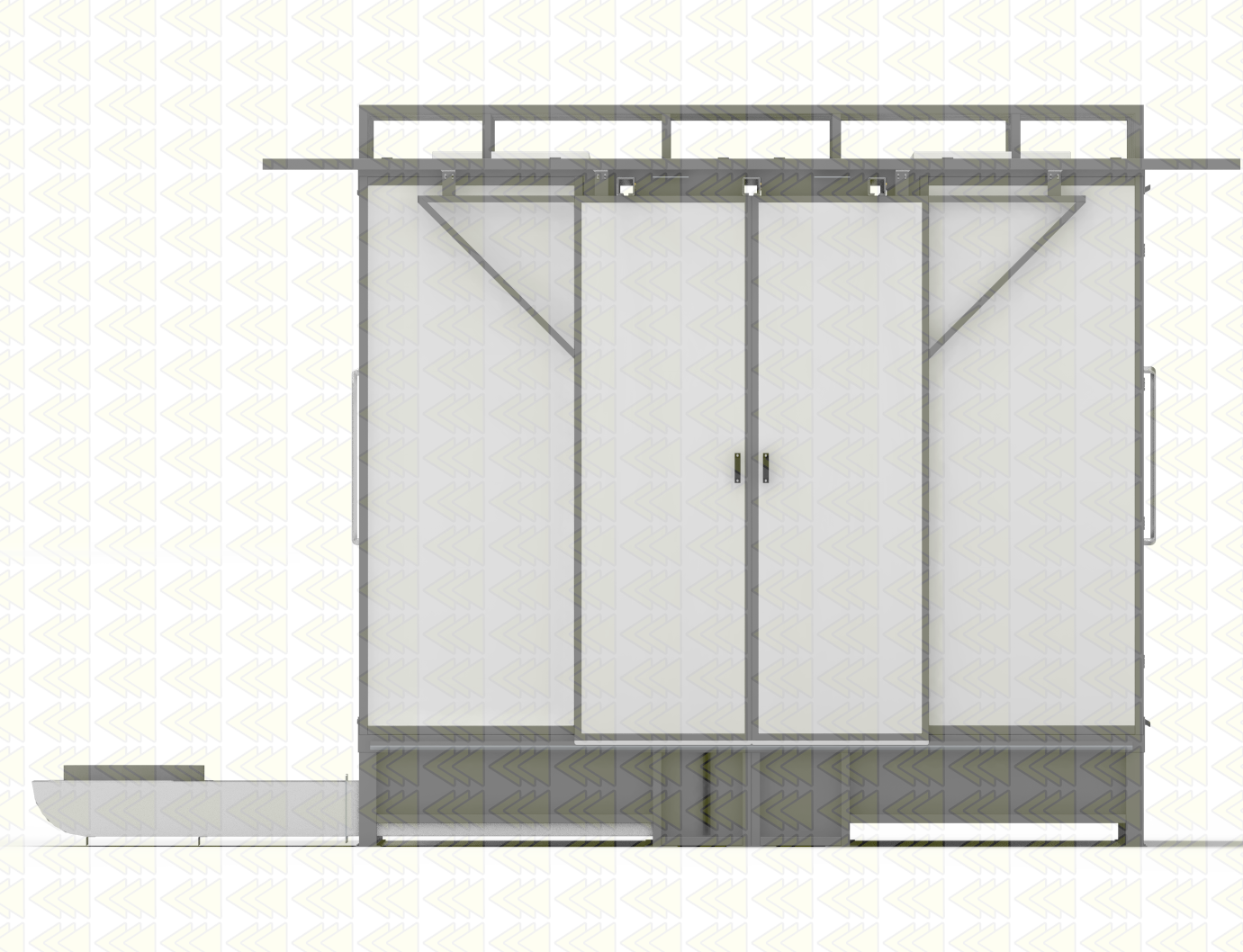

Standard models

| Cab model |

Floor area dimension |

Height

|

Dust Collector Power | External dust collector | Air flow |

Filtration |

Filtration output air |

External Dust Collector | Sliding doors |

| KPT-1520400 | 2000x4000 | 2000mm | >= 22kW | ? | Vertical | ? | ? | ? | option |

| KPT-2030600 | 2000x6000 | 3000mm | >= 22kW | ? | Vertical | ? | ? | ? | option |

| KPT-2030900 | 2000x9000 | 3000mm | >= 22kW | ? | Vertical | ? | ? | ? | option |

| KPT-3020400 | 3000x4000 | 2000mm | >= 22kW | ? | Vertical | ? | ? | ? | option |

| KPT-3030600 | 3000x6000 | 3000mm | >= 22kW | ? | Vertical | ? | ? | ? | option |

| KPT-3030900 | 3000x9000 | 3000mm | >= 22kW | ? | Vertical | ? | ? | ? | option |

| These are examples of standard cabins - other dimensions, configurations, available on individual request. | |||||||||

Cleanliness

|

Input air filter |

|

Paint filtration and air purification The type of filters used in tunnel cabin dust collectors is much more efficient than in the case of standard cabins, which means that the air sucked into the cabin returns back to the hall very well cleaned of solid particles. |

|

Lighting |

Comfort

|

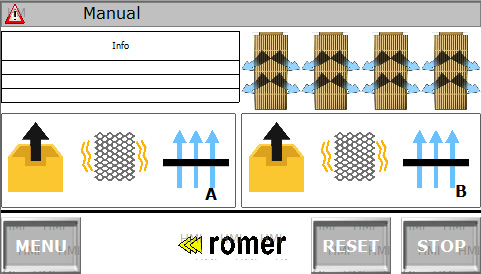

Adjustable thrust Each of the dust collectors used in the tunnel cabins has a built-in inverter that can be controlled from the touch panel. |

|

Touch controls ROMER cabins are equipped with 4" color touch screens. Cabin operation is intuitive, it has 3 modes: automatic (timed), automatic (based on a clogged filter sensor) or manual. |

|

|

Automatic filter cleaning The electronic system of automatic filter cleaning has a range of adjustment of cleaning frequency and firing time. Each filter is cleaned separately, the filters can also be cleaned manually using the buttons.

We know from experience that it is difficult for the operator to enforce filter cleaning. Thanks to this system, the operator will no longer have to think about it. |

|

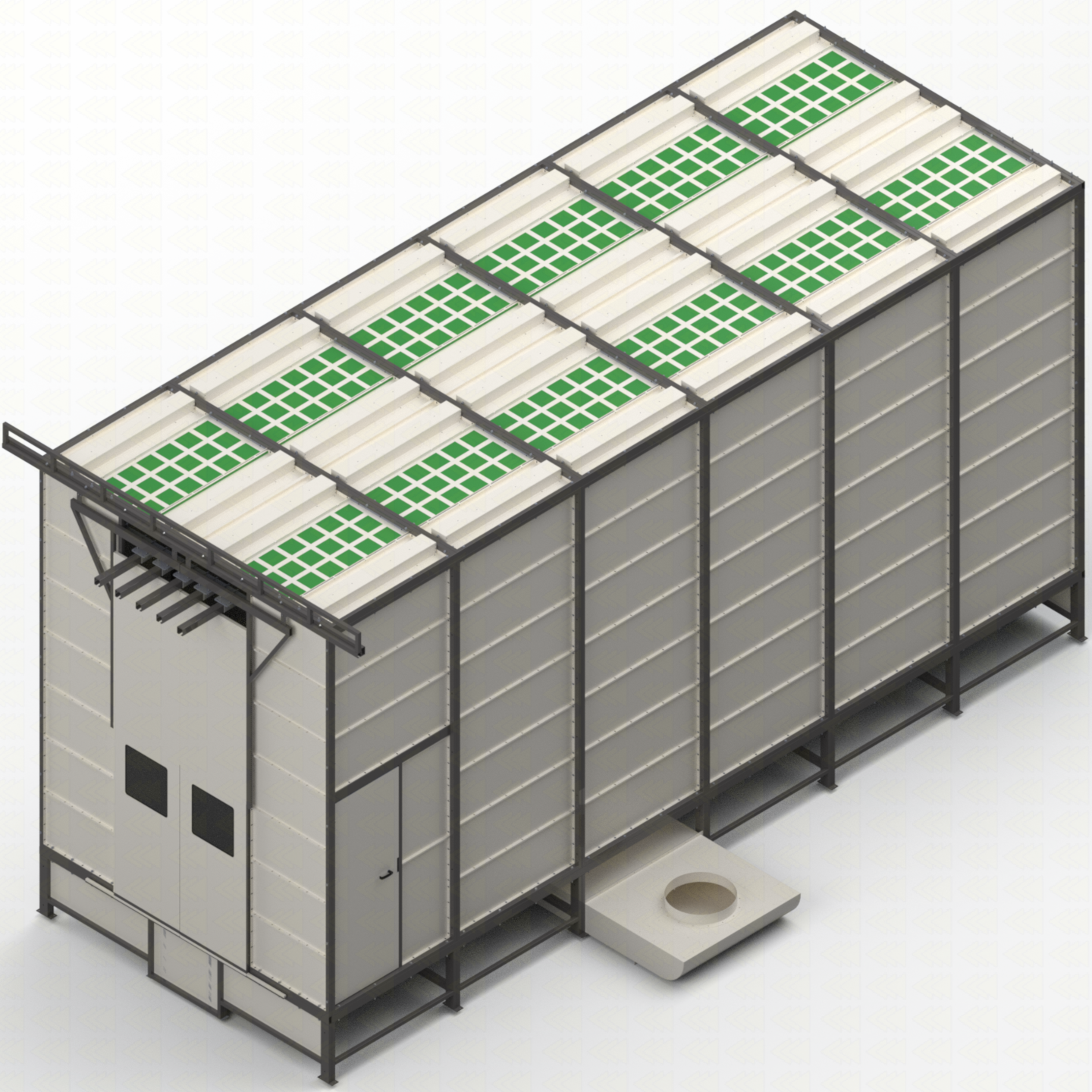

Environmental cleanliness When using standard booths, it is difficult to keep the spraying area clean. It depends on many factors and the operator himself. In the case of using a tunnel cabin, keeping the hall clean is much easier, because the cabin is enclosed with walls and the spraying takes place inside. |

|

|

Cab Puller The cabin, by dragging the sling beams within the cabin, improves work efficiency, thus relieving the painter, who no longer has to move them manually. |

|

Filter clogging sensor A sensor is installed in the cabins that queues filters for cleaning when they become clogged. The system also informs you when the filters are exhausted |

|