Construction

|

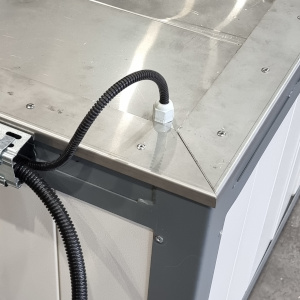

Inner sheathing made of stainless steel |

|

|

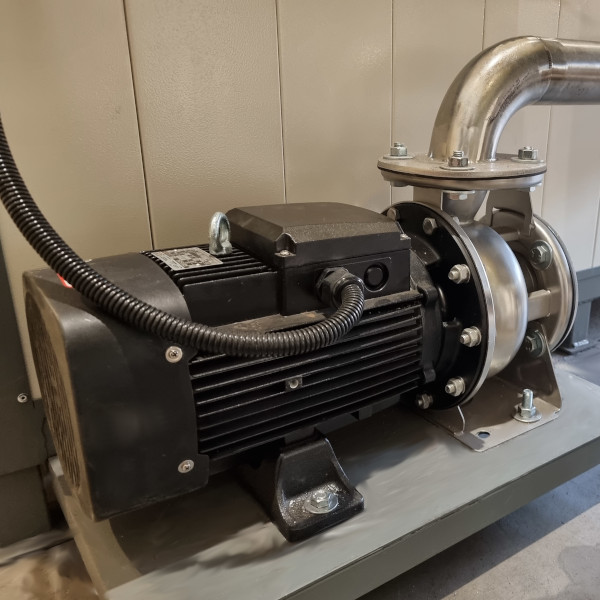

Pumps made of stainless steel |

|

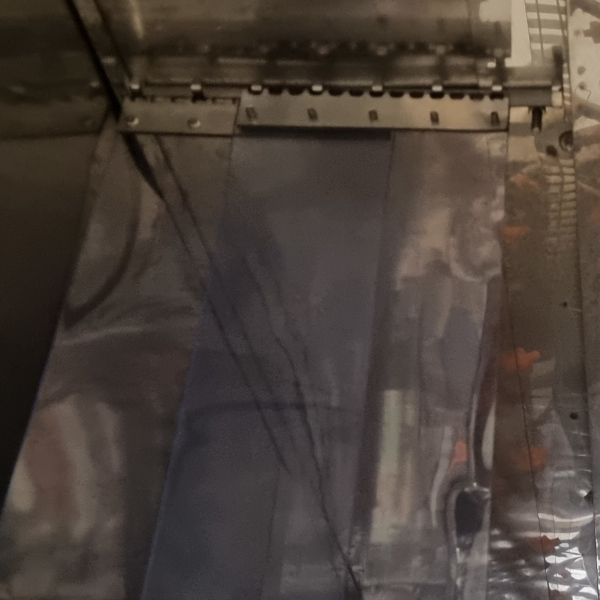

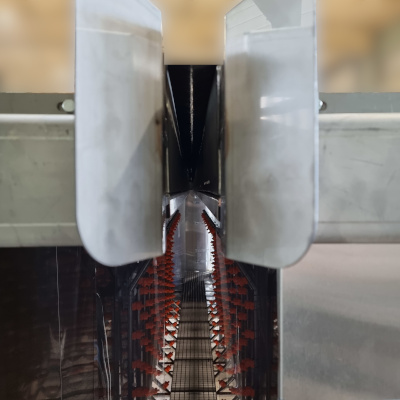

Zones separated by width-adjustable curtains |

|

|

Easy access to the tanks from outside the car wash |

|

Drip zones between processes |

|

|

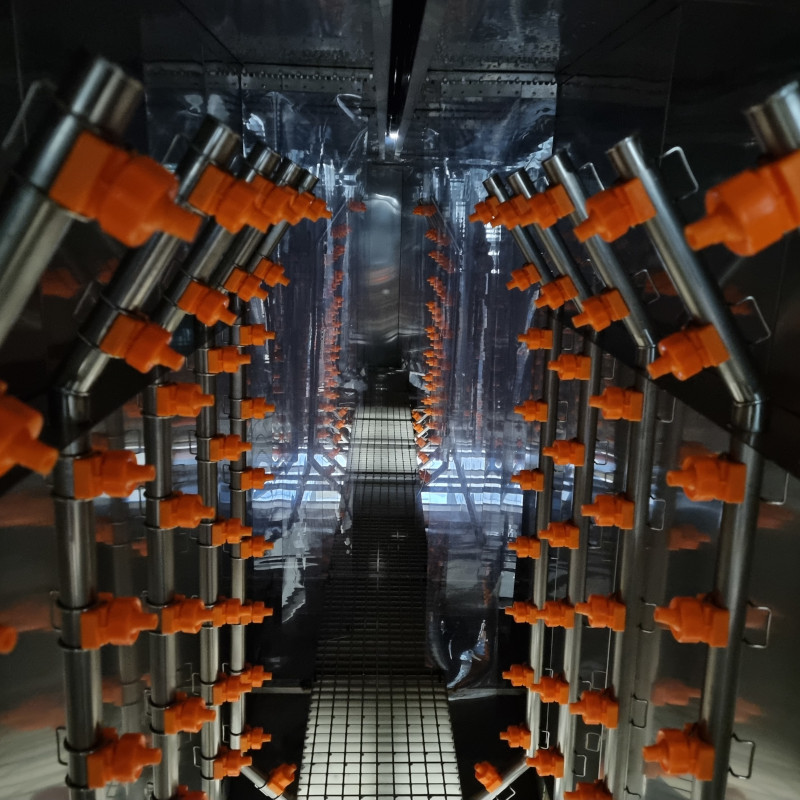

Angle profiled spray pipes |

|

Modular construction |

|

|

Insulated housing, made of easily removable panels |

|

Bars for the operator to enter the car wash |

|

|

Pre-filtration of each process |

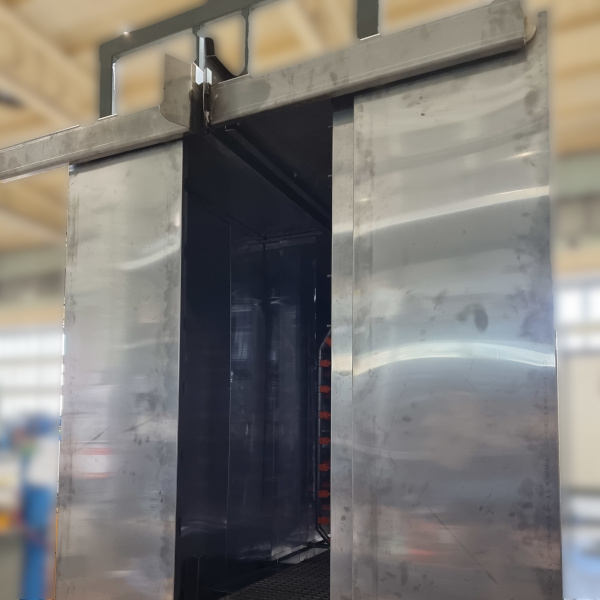

| The width of the inlet to the car wash is regulated by sliding doors |

|

|

Plastic interchangeable nozzles with adjustable spray angle |

Benefits

| Low liquid transfer |

|

|

High washing accuracy |

|

Closed-circuit washing |

|

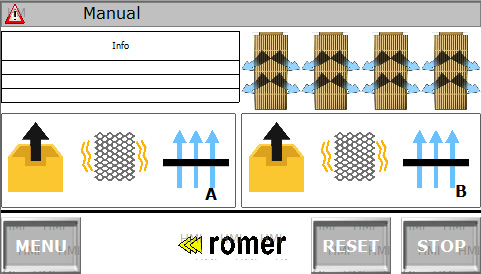

Control

|

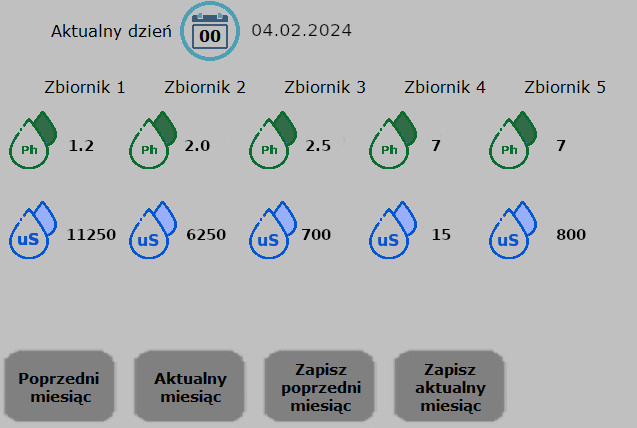

Intuitive 7" |

|

|

Login for technologists and operators |

|

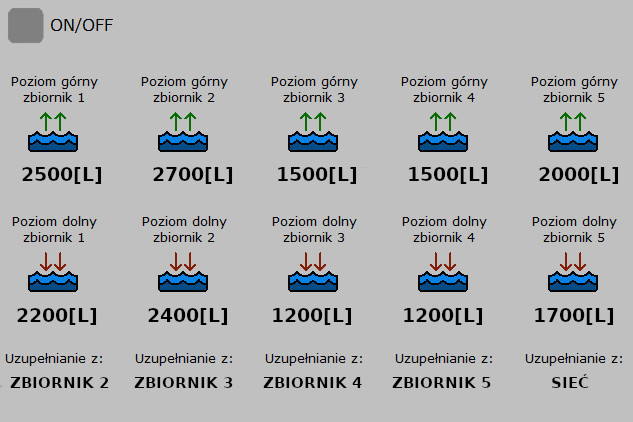

Programming of cascade levels and scrubbing refresh |

|

|

touch panel control

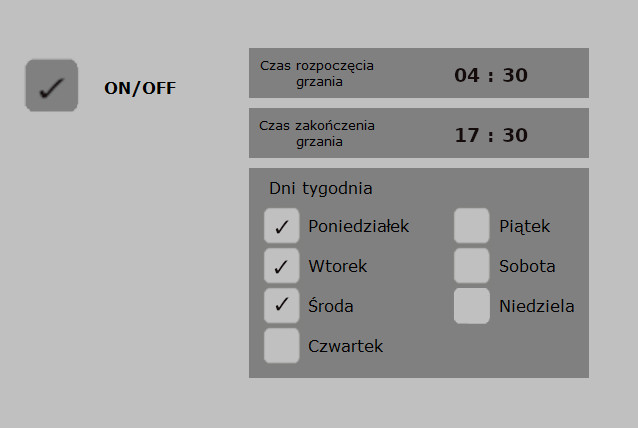

Built-in car wash work calendar |

| Built-in calendar to monitor conductivity, pH of chemical treatments and washes |

|

|

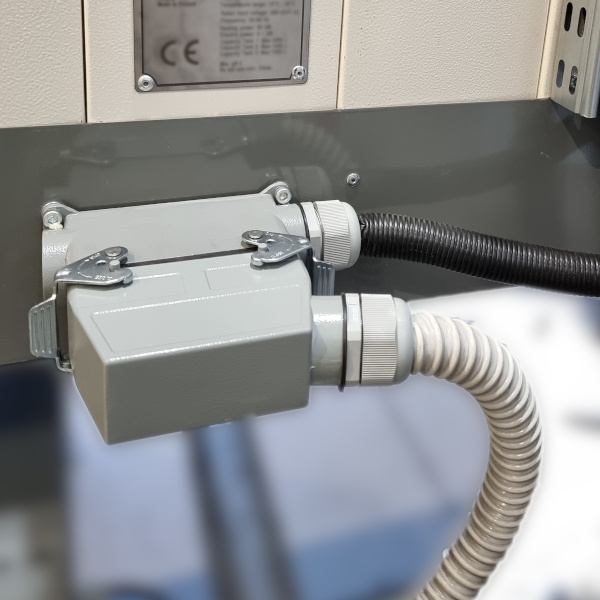

Modbus communication with other master controllers |

Equipment

|

Filtration of the chemical treatment with a flow filter |

|

|

Stepless measurement of the amount of liquid in each tank |

|

Pipelines equipped with pressure gauges |

|

|

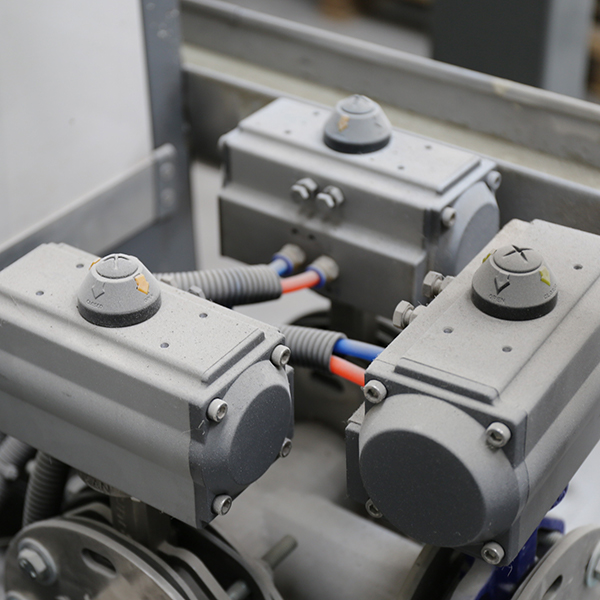

Automatic cascade between processes - controlled by pneumatic valves |

|

Direct heating with burner or electric heaters |

|

|

Fume hoods along the entire length of the rail |

|

Additional sealing under the rail |

|

|

Flows on the pumps are regulated manually with butterfly valves, optionally with inverter inverters |